JAMG HE Light Weight PLA Filament

| Brand: JAMG HE |

| SKU: LW-PLA |

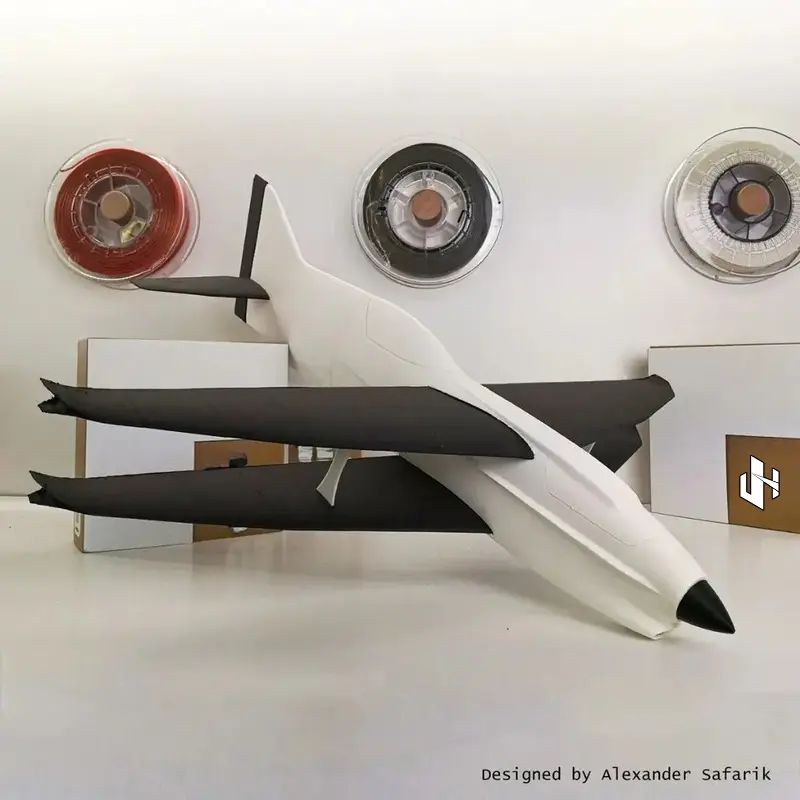

3D printing of Parts from JAMG HE Light Weight PLA Filament

LW-PLA is the first filament of its kind to use active foam technology to create low weight and low-density PLA parts. At about 230 ° C, the material begins to foam and increases its volume almost three times.

Users can reduce material flow by 65% to achieve lighter weight parts, or use the expansion characteristics to effectively reduce printing time by using large layer heights or single extra-thick perimeters.

Active foam technology, how does it work?

The most important input variables for controlling the expansion are speed, temperature and flow. This allows users to vary the density of the material for different parts of the model.

following 4-step process to determine the maximum extent at a given speed, temperature and flow.

- Print the cubes at a specified speed at temperatures between 200 ° C and 280 ° C

- Measure the circumference thickness of each cube and note the highest expansion temperature.

- Print a cube in increments of decreasing flow at the temperature specified in step 2.

- Choose the print where the circumferential thickness matches the nozzle size.

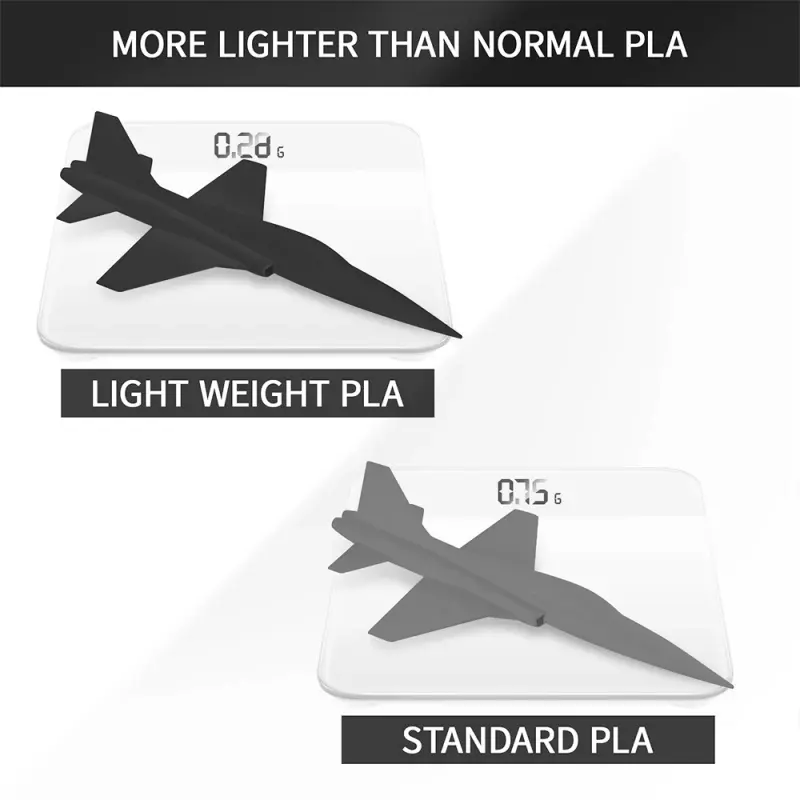

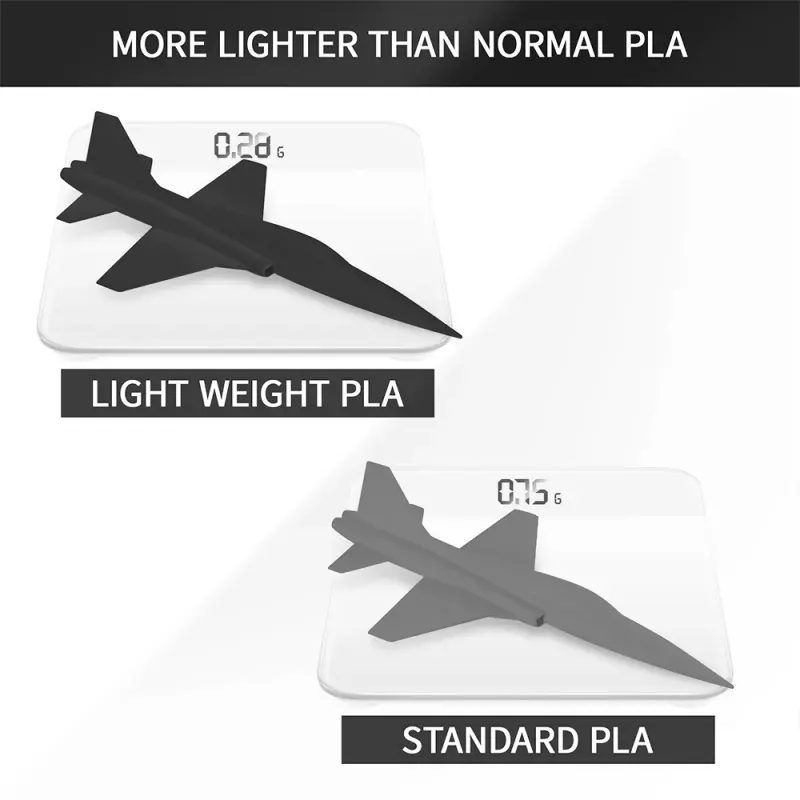

Up to 65% weight reduction.

Because of the expanding nature of the material, users can reduce flow while still printing dimensionally accurate models. Users can achieve a weight reduction of 65% compared to conventional PLA.

3D-Print more!

Decreasing flow means less filament. As a result, two to three times as many parts can be printed with LW-PLA as with a normal PLA spool.

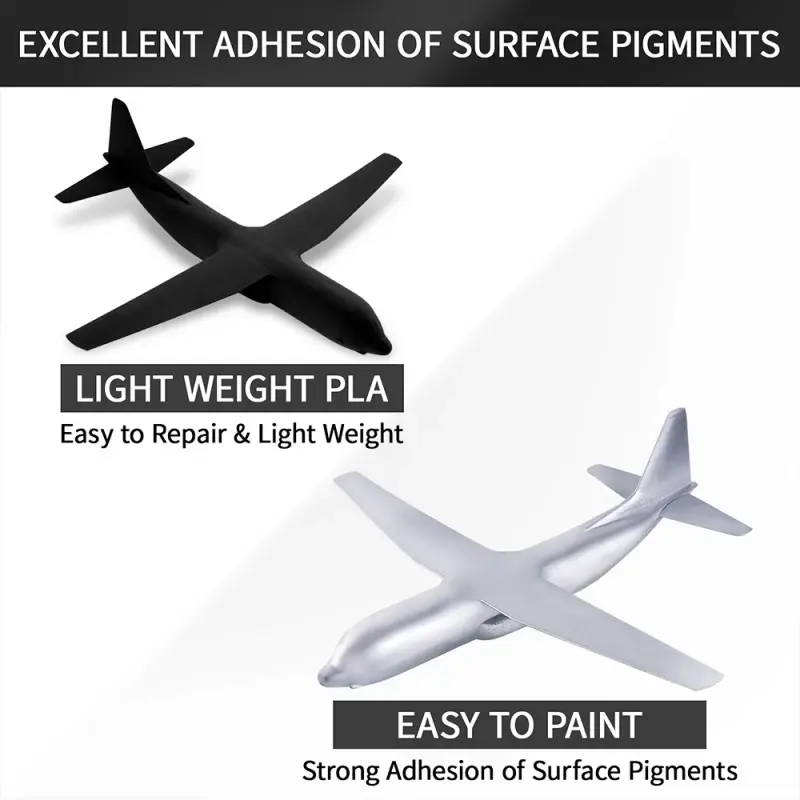

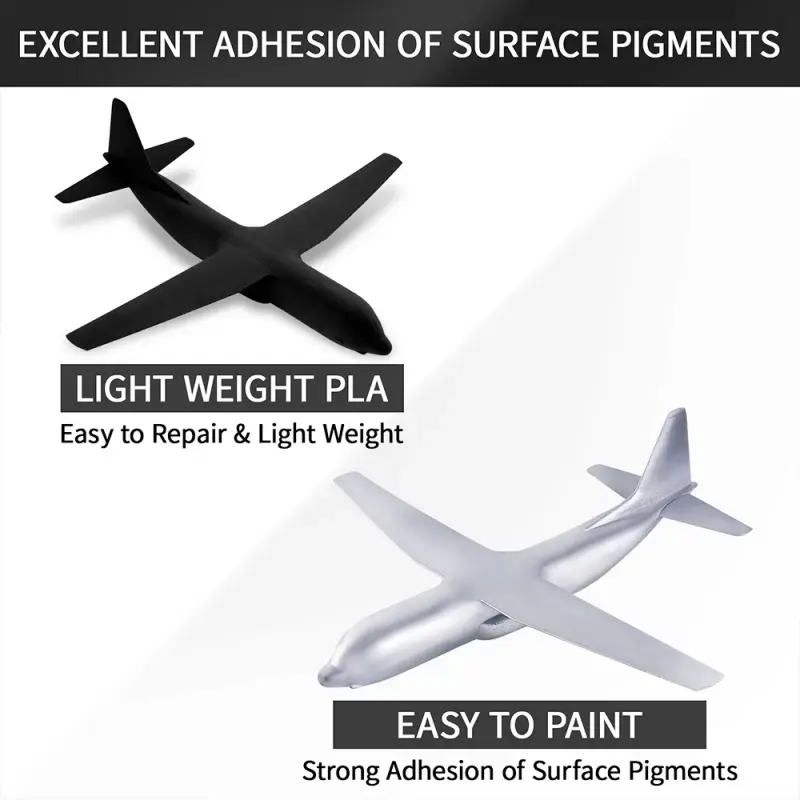

Excellent surface quality.

LW-PLA prints in a fantastically matte surface and is very easy to rework.

JAMG HE LW-PLA

More Lighter Than Normal PLA Filament

Light Weight PLA

JAMG HE Light weight PLA is Easy to Repair and paint , There is strong adhesion of surface pigments

Matte Finish

Light Weight PLA has matte finish and hide the layers for good surface finish

| Filament Properties Table | |

|---|---|

| 3D PRINTING FILAMENT | PLA-LW |

| Density(g/cm3) | 1.2 |

| Heat Distortion Temp(℃,0.45MPa) | 53 |

| Melt Flow Index(g/10min) | 8.1(190℃/2.16kg) |

| Tensile Strength(MPa) | 32.2 |

| Elongation at Break(%) | 68.9 |

| Flexural Strength(MPa) | 41.31 |

| Flexural Modulus(MPa) | 1701 |

| IZOD Impact Strength(kJ/㎡) | 8.58 |

| Durability | 4/10 |

| Printability | 9/10 |

| Recommended printing parameters | |

| Extruder Temperature(℃) | 190 – 270℃ |

| Bed temperature(℃) | 45 – 60°C |

| Fan Speed | 100% |

| Printing Speed | 40 – 100mm/s |

| Heated Bed | Optional |

| Recommended Build Surfaces | Masking paper, PVP solid glue, PEI |

| Feature | |

| Flexible | —— |

| Elastic | —— |

| Impact Resistant | —— |

| Soft | —— |

| Composite | —— |

| UV Resistant | —— |

| Water Resistant | —— |

| Dissolvable | —— |

| Heat Resistant | —— |

| Chemically Resistant | —— |

| Fatigue Resistant | —— |

| Need drying | —— |

| Heated Bed Required | —— |

?unique=9bddf5e)

?unique=9bddf5e)