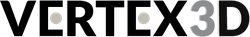

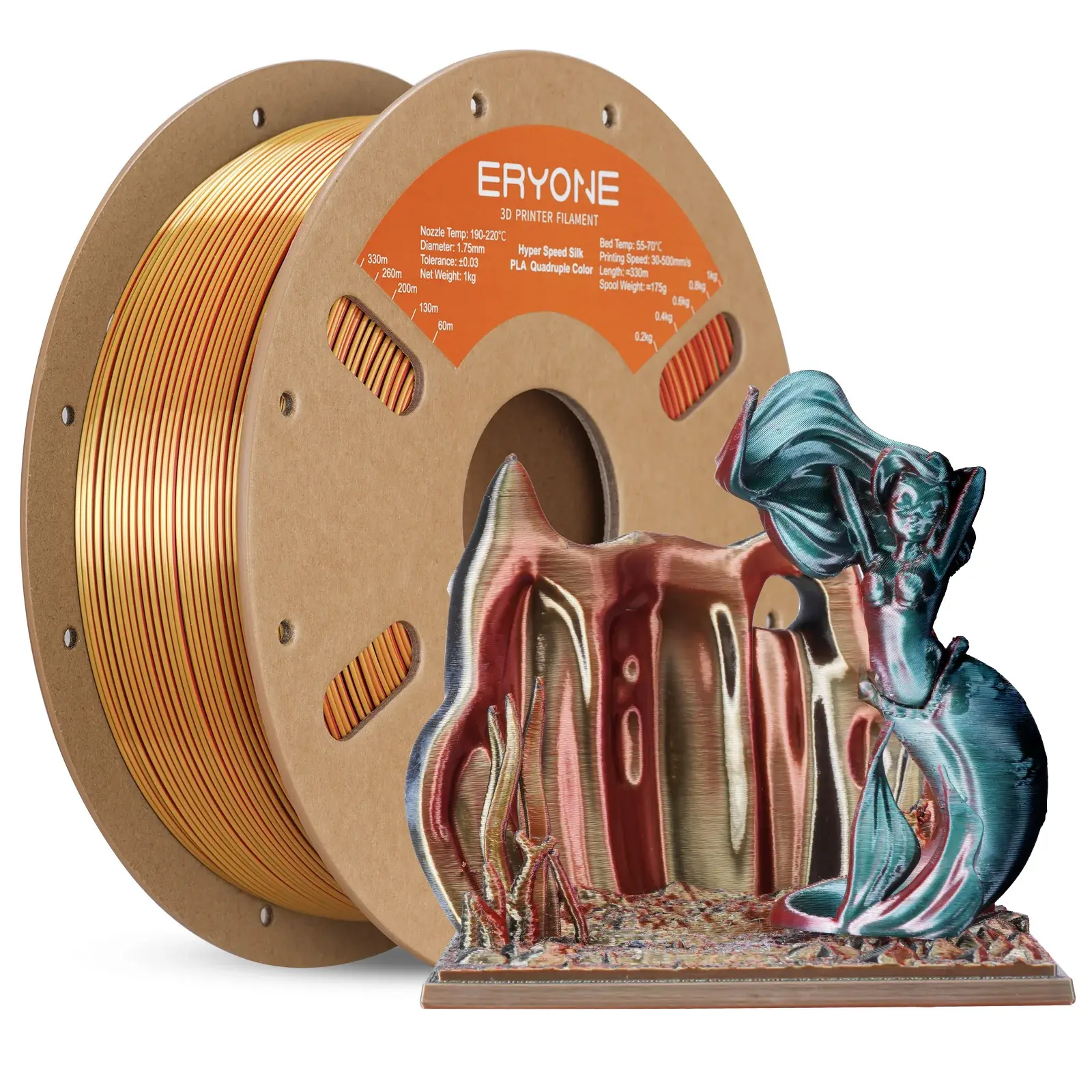

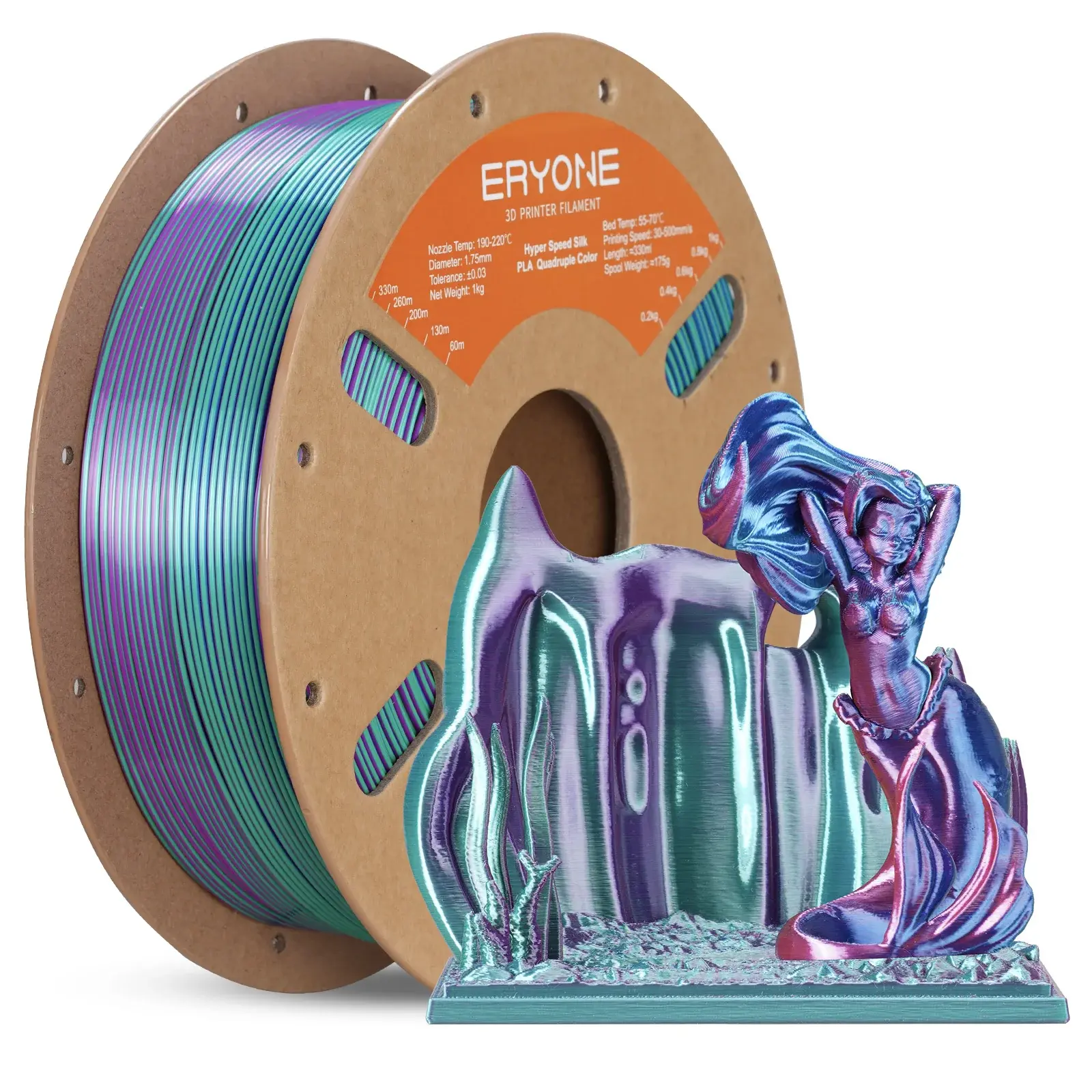

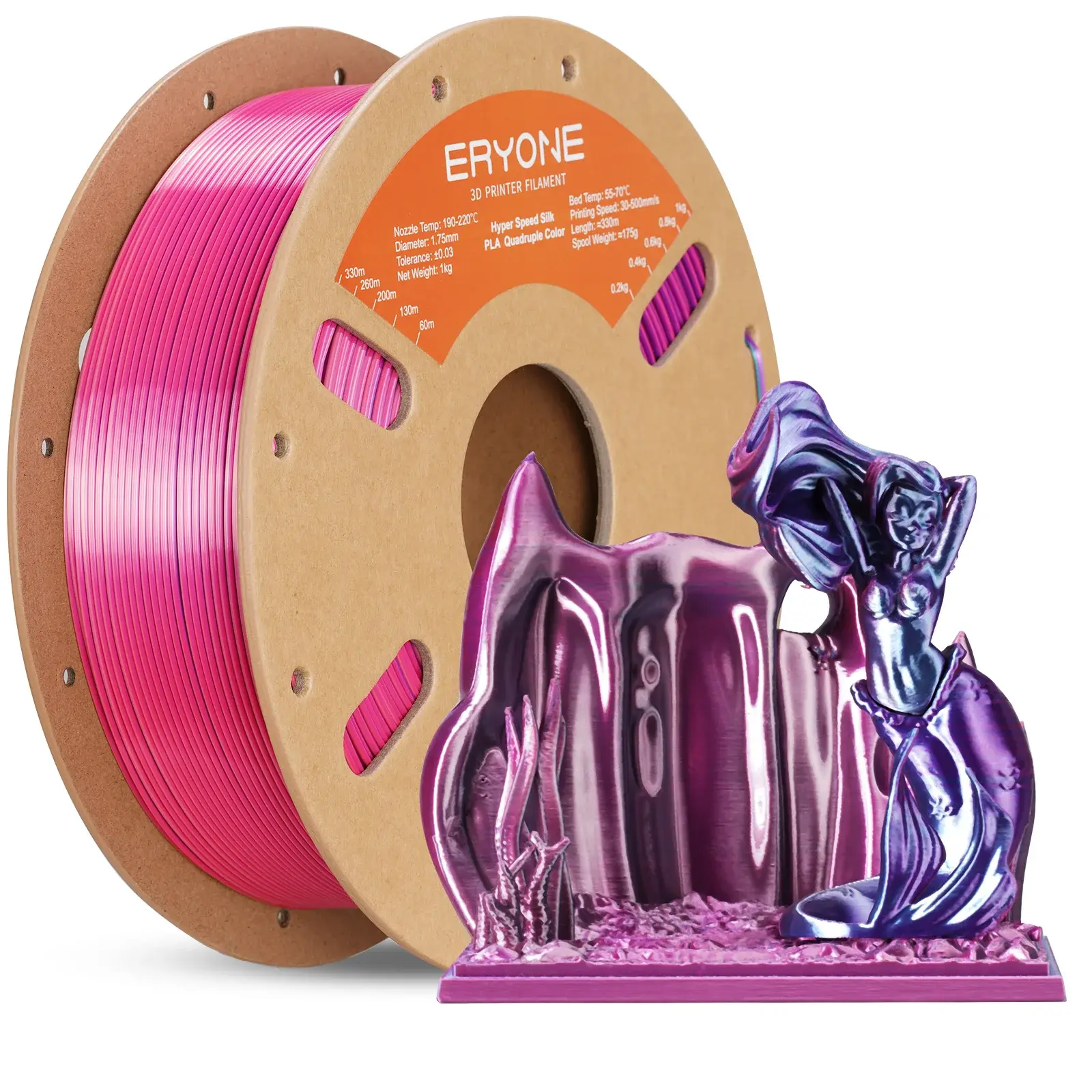

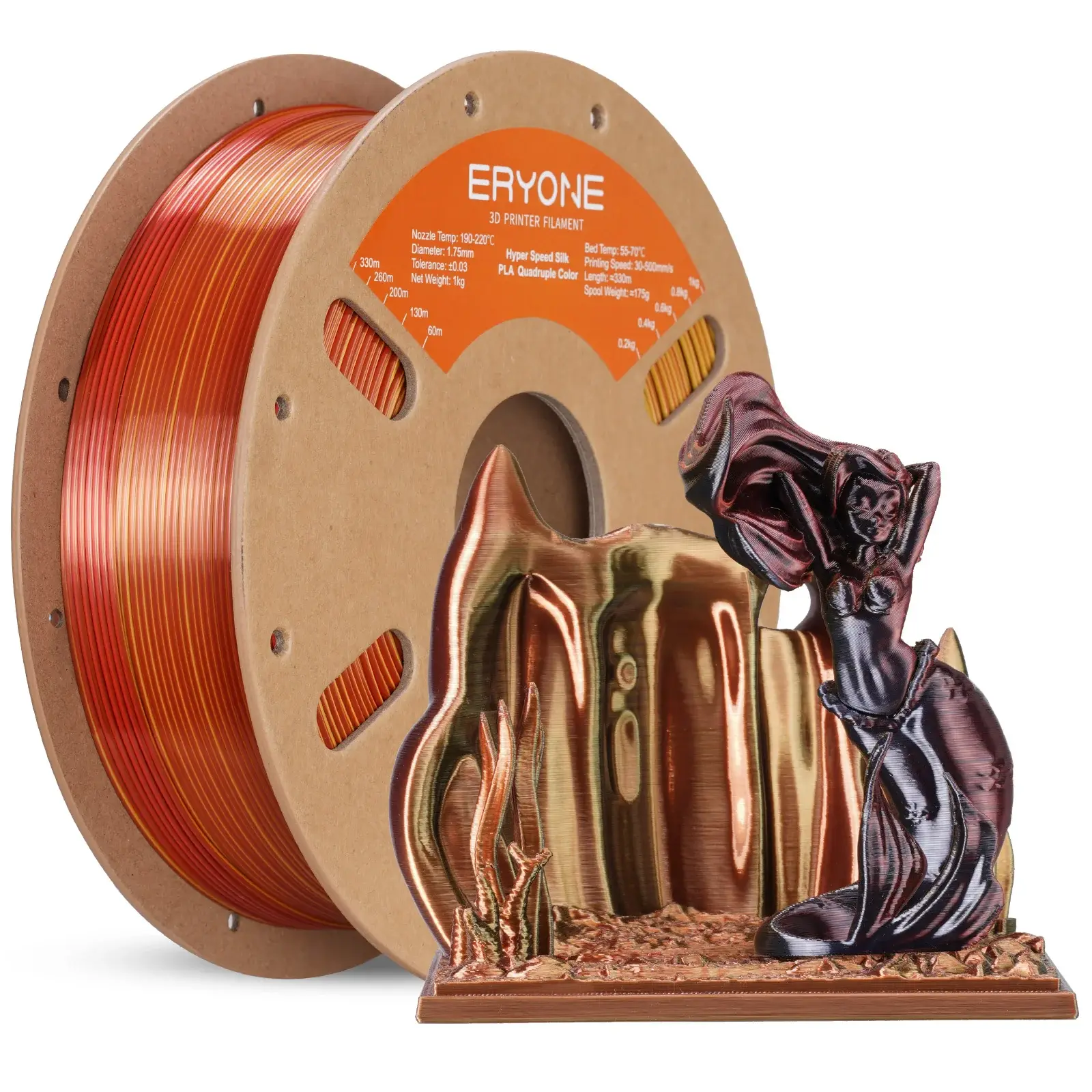

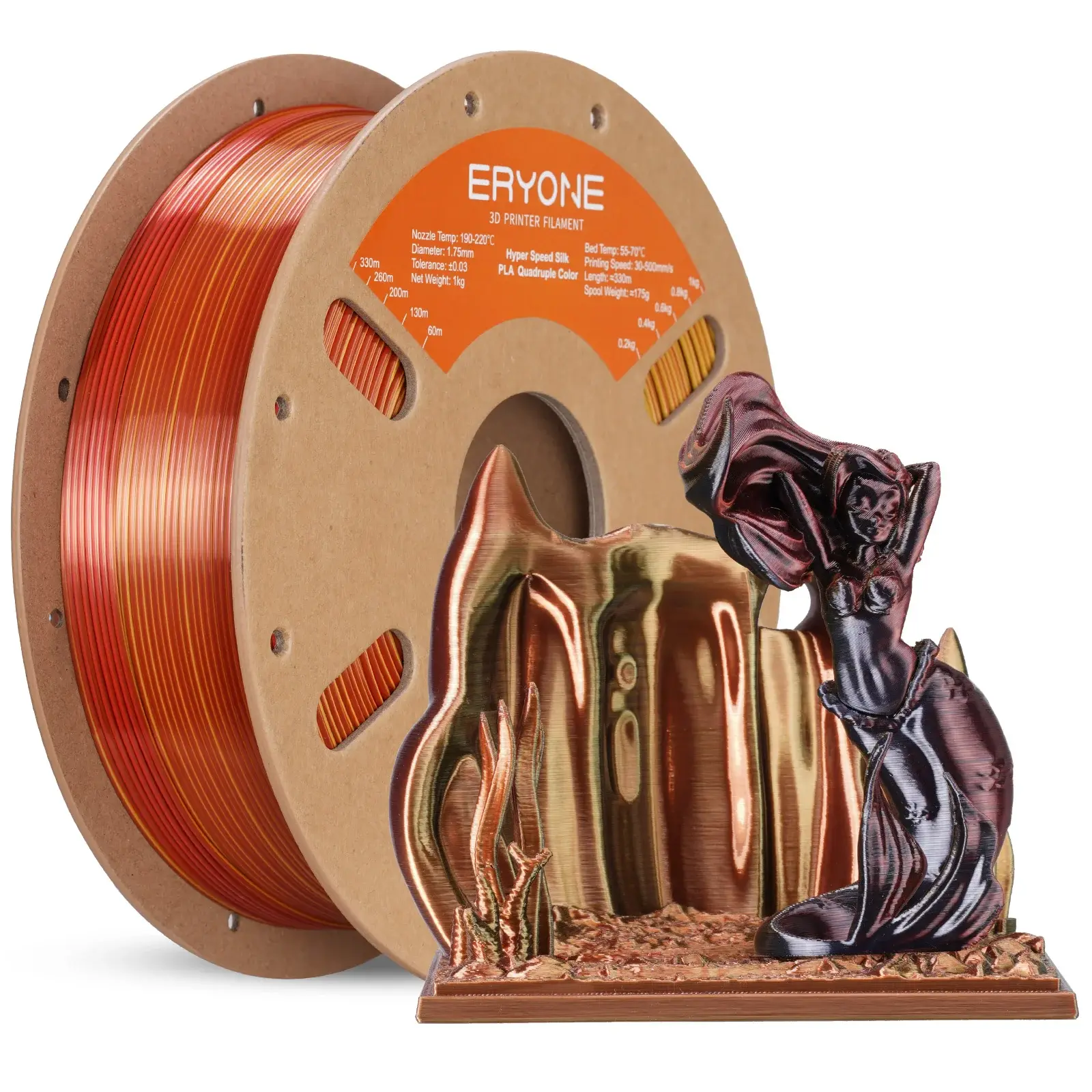

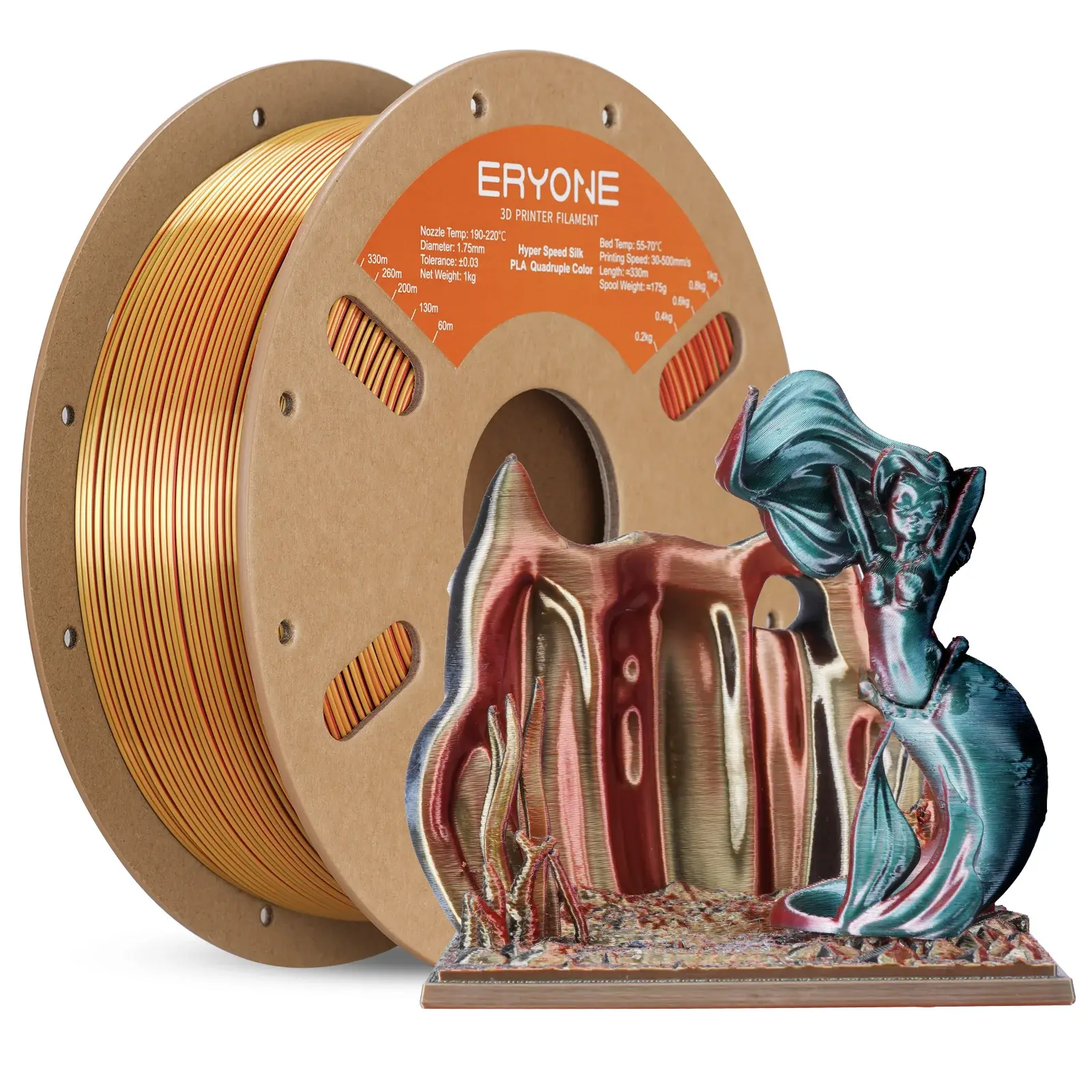

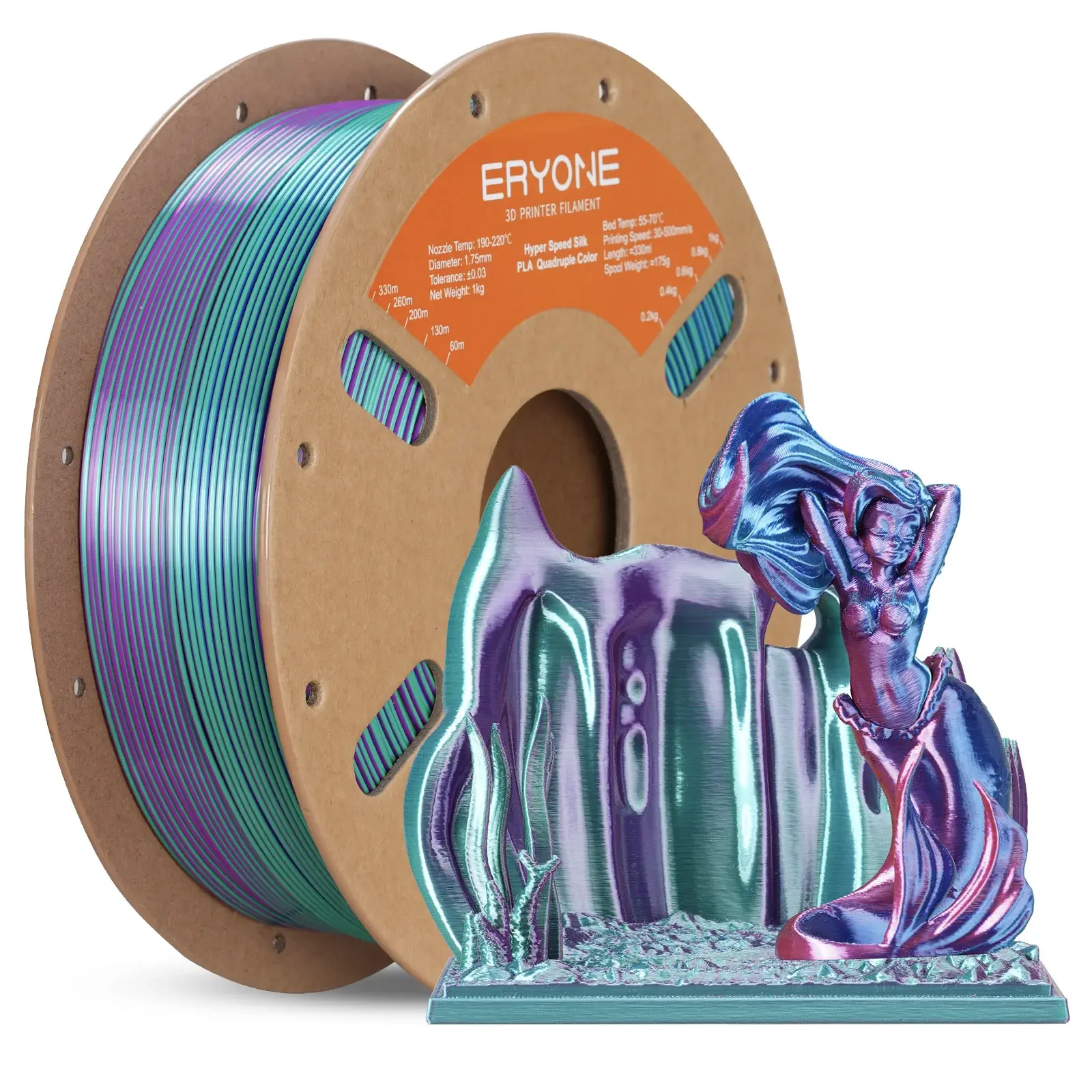

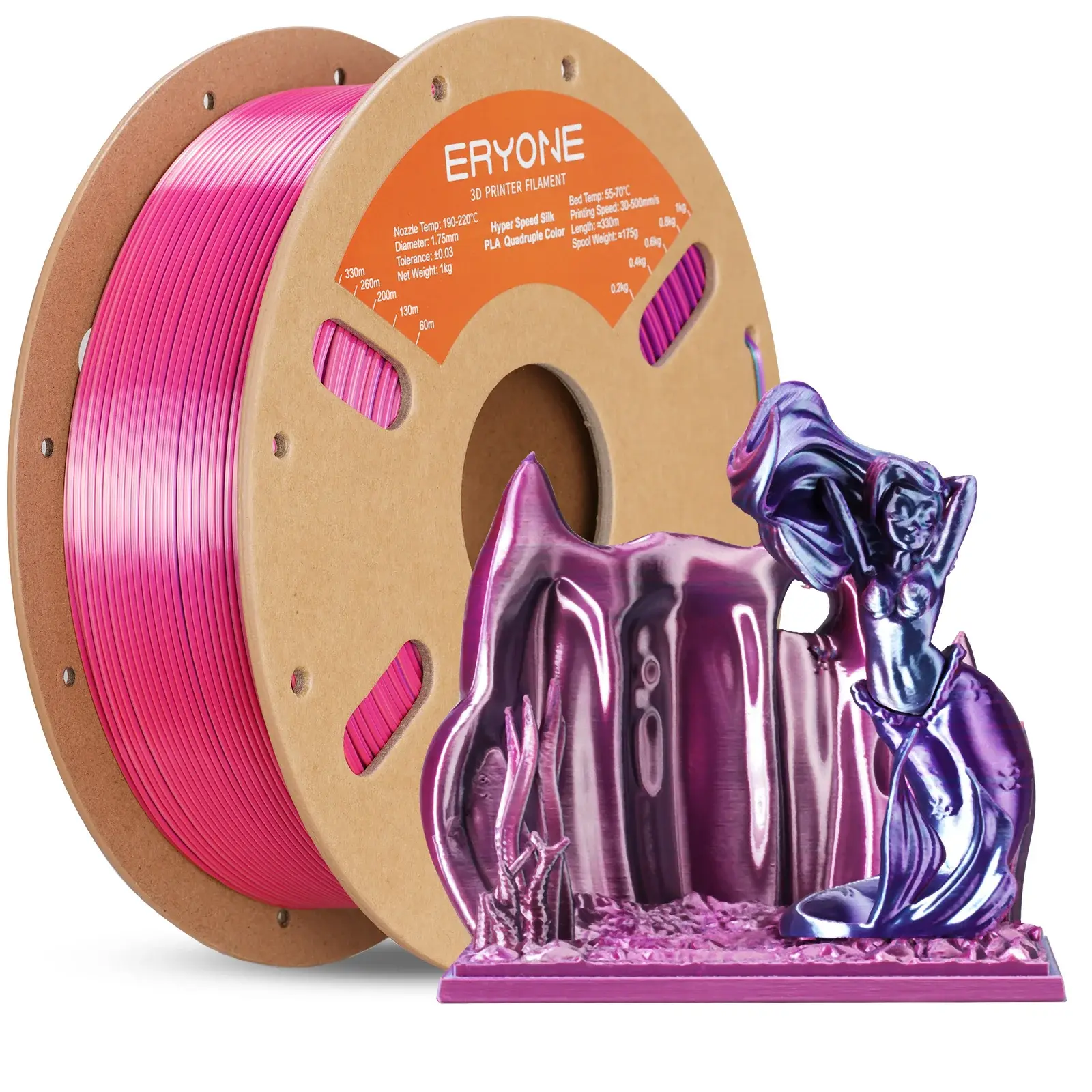

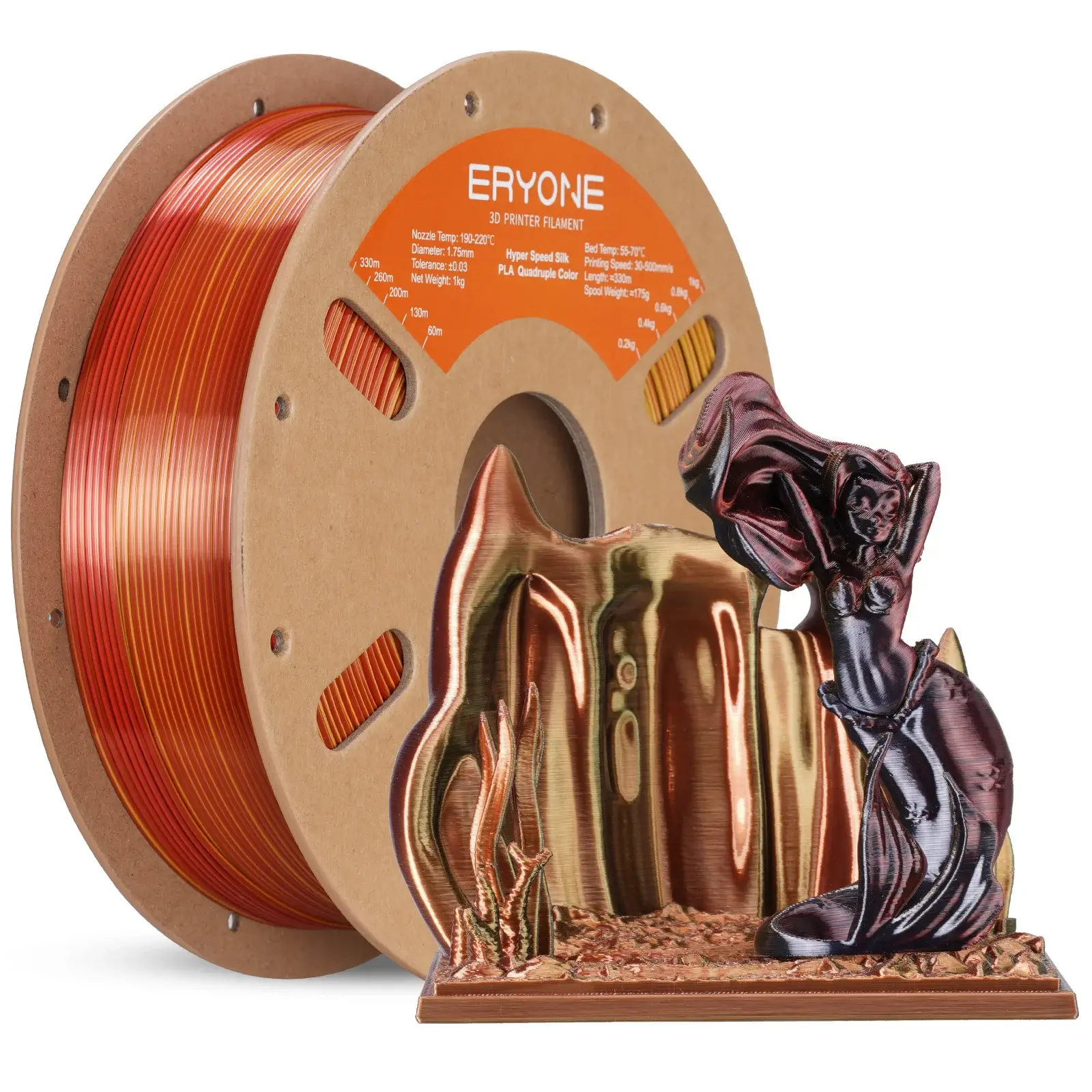

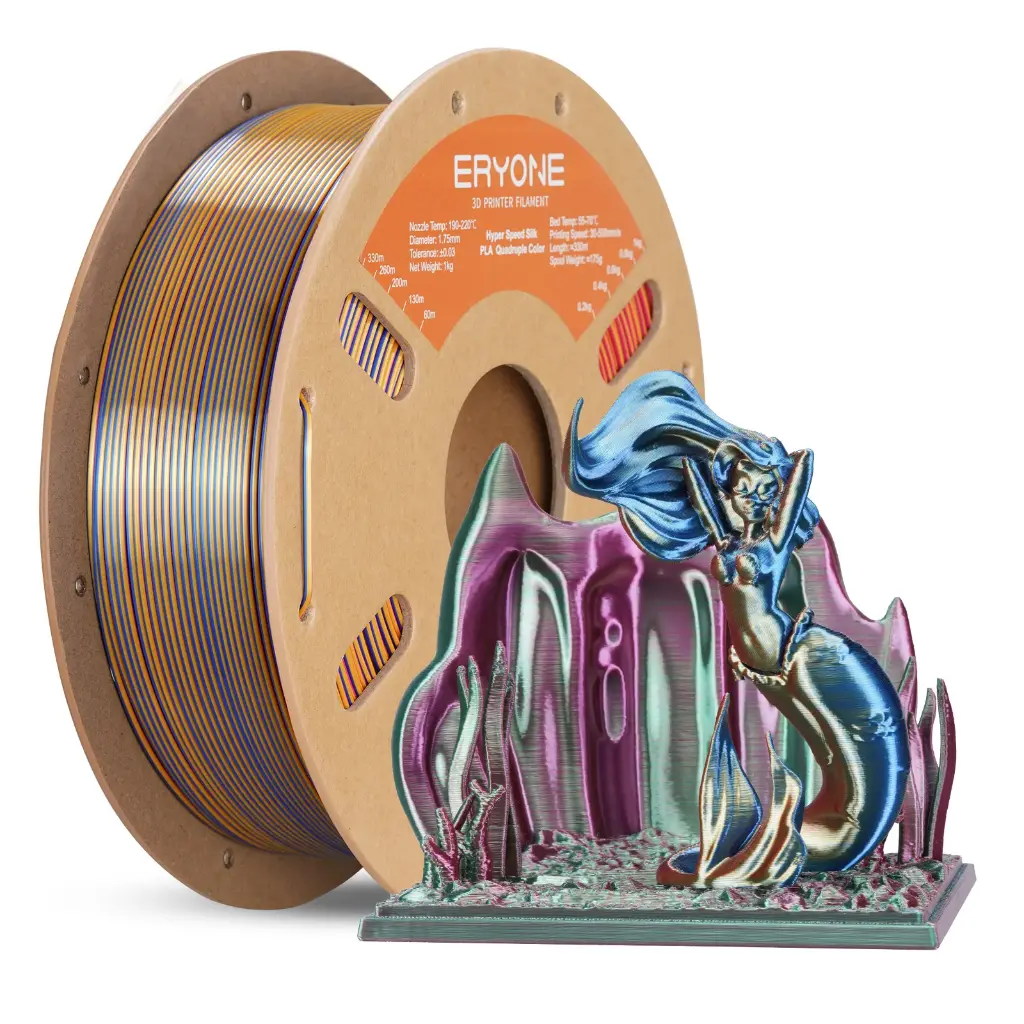

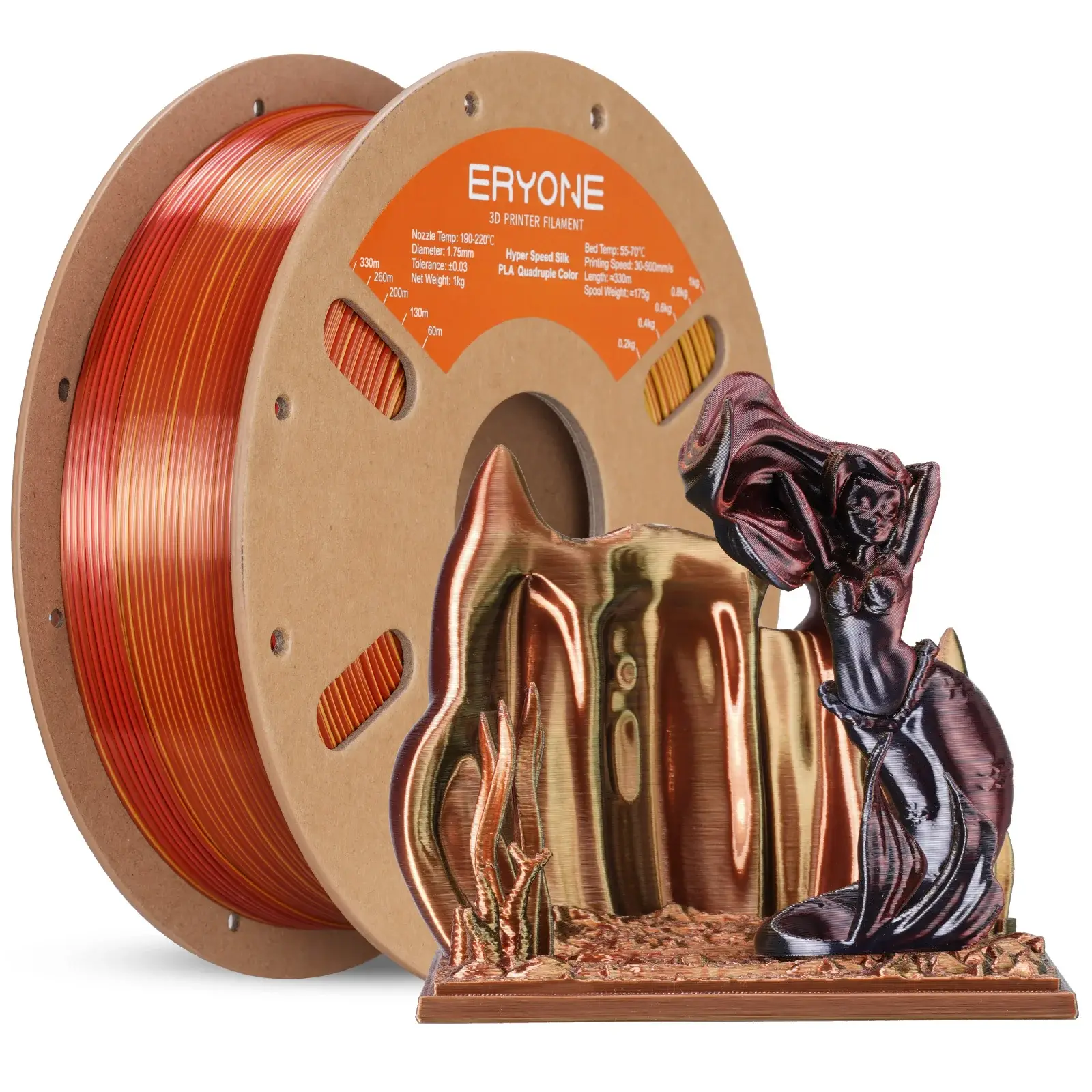

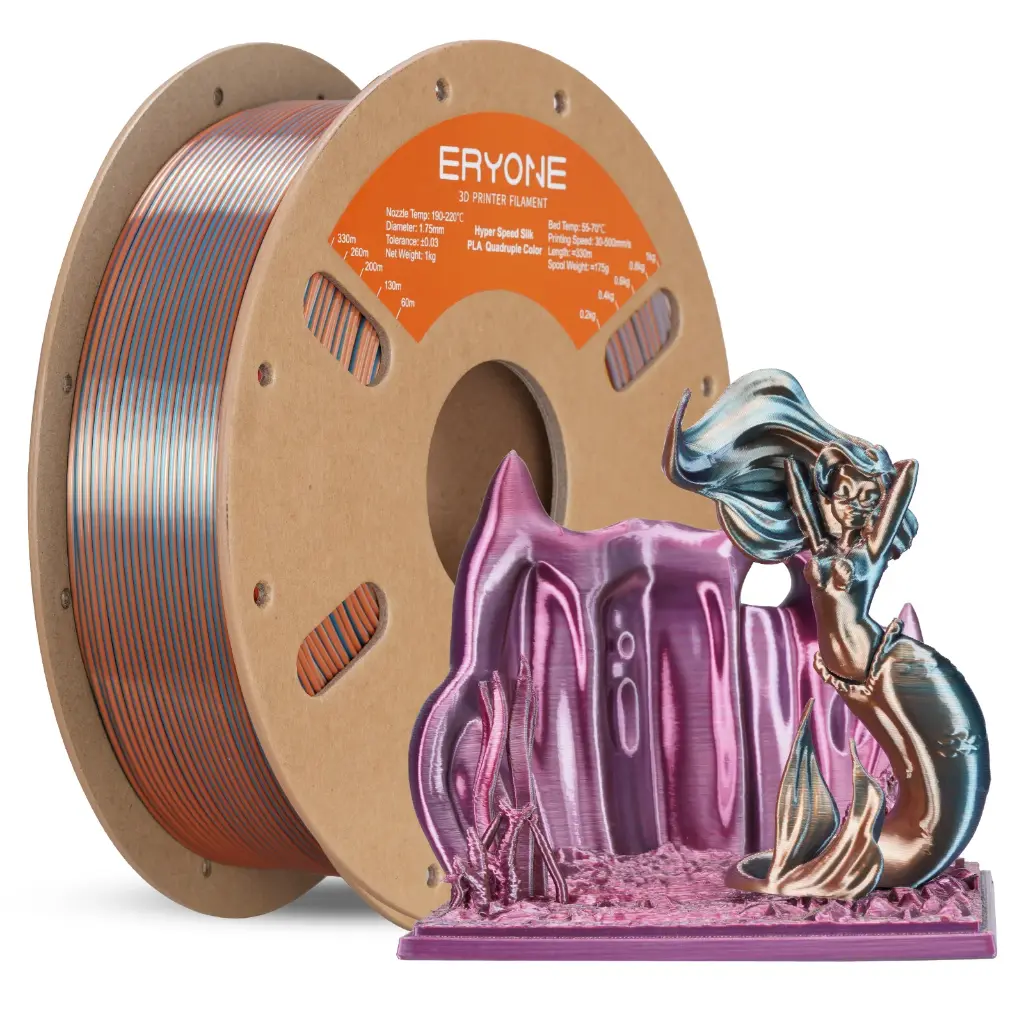

ERYONE Hyper Speed Four Colors Silk PLA Filament for 3D Printers

| Brand: ERYONE |

Hyper Speed Four colors Silk PLA Filament for 3D Printer

- The Eryone High-Speed Silk PLA is a material with a thoroughly improved

- formulation, offering significantly enhanced printing speeds compared to standard silk

- PLA, reaching up to 500 mm/s. Additionally, its tensile strength has been notably

- increased, with the Z-axis tensile strength reaching 20 MPa. This high-speed silk PLA

- material delivers a more lustrous finish, presenting a silk-like appearance. The

- brightness can be controlled by adjusting the temperature and speed: higher

- temperatures and slower printing speeds result in increased brightness.

Part I: Suggests Printing Parameters

| Parameter | Set up |

| Nozzle temperature | 190℃-220℃ |

| Bed temperature | 55-70℃ |

| Bed material | glass, PEI, spring steel plate |

| Bottom printing temperature | 190℃-220℃ |

| Sealed printing | Open Printing/closed printing |

| Printing speed | 30-500mm/s |

| Drying conditions | 65℃-75℃,12H |

Part II: Physical Properties of Materials

| Property | Testing Method | Unit | Typical Value |

| Density(g/cm³ at 21.5 ° C) | ASTM D792 (ISO 1183, GB/T 1033) | g/cm³ | 1.32 |

| Vicat Softening Temperature(° C) | ASTM D1525 (ISO 306 GB/T 1633) | ℃ | 56 |

| Heat distortion temperature(° C | ASTM D648 1.8MPa 0.45MPa | ℃ | 50 |

| Glass transition temperature (° C) | DSC, 10 ° C/min | ℃ | 57 |

| Melt Index(g/10 min) | 220 ° C, 10kg 240 ° C, 2.16 kg | g/10min | 20±1.5 |

Part III: Mechanical Properties of Printed Samples

| Property | Test conditions | Test standards | unit | Typical Value |

| Tensile strength X-Y | 50mm/min | GB/T 1040.4 | MPa | 62.7 |

| Elastic modulus X-Y | 50mm/min | GB/T 1040.1-2006 | MPa | 1932.1 |

| Elongation at break X-Y | 50mm/min | GB/T 1040.4 | % | 2.3 |

| Tensile strength X-Z | 50mm/min | GB/T 1843 | MPa | 19.1 |

| Elastic modulus X-Z | 50mm/min | GB/T 1040.1-2006 | MPa | 1873.5 |

| Elongation at break X-Z | 50mm/min | GB/T 1040.4 | % | 1.9 |

| Bending strength | 2mm/min | GB/T 9341 | MPa | 86.7 |

| Bending modulus | 2mm/min | GB/T 9341 | MPa | 2917.3 |

| Charpy Impact strenght | 2.75J | GB/T 1843 | kJ/m2 | 3.8 |

Note: All splines are printed under the following conditions: printing temperature=215 ° C, printing speed=80mm/s, base plate 60 ° C, filling=100%, nozzle diameter=0.4mm

Disclaimers

The values given in this data table are for reference and comparison only. They

should not be used for design specifications or quality control. The actual value may

vary depending on the printing conditions. The final performance of printed

components depends not only on the material, but also on the component design, environmental conditions, printing conditions, and so on. Product specifications are

subject to change without prior notice.

)?unique=77ebc44)

%20(1).webp?unique=77ebc44)

%20.webp?unique=77ebc44)

%20.webp?unique=77ebc44)

.webp?unique=77ebc44)

%20.webp?unique=77ebc44)

)?unique=77ebc44)

%20(1).webp?unique=77ebc44)

%20.webp?unique=77ebc44)

%20.webp?unique=77ebc44)

.webp?unique=77ebc44)

%20.webp?unique=77ebc44)