Creality K1 /K1 Max Bimetal nozzle in Pakistan

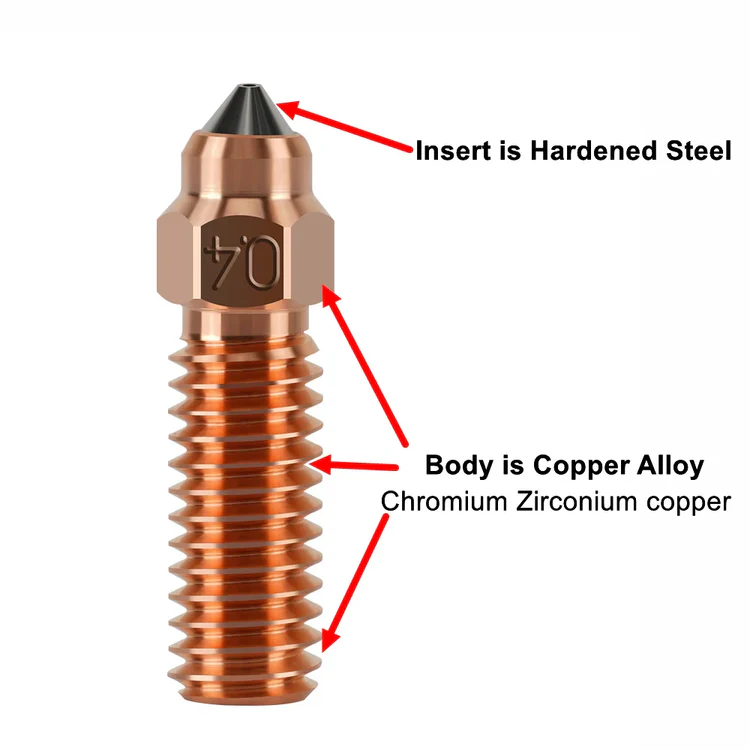

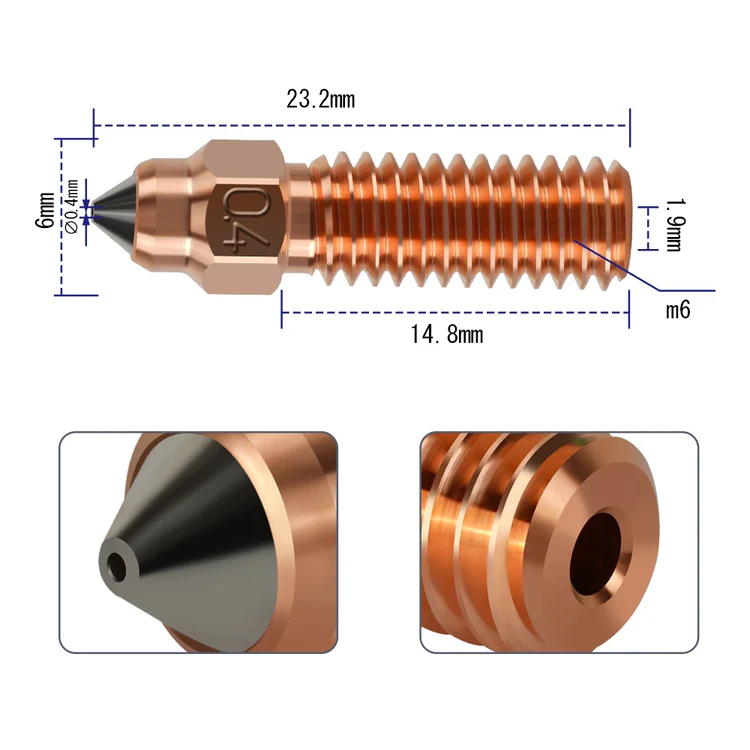

Ender 3 V3 KE Nozzle Bimetal Chromium Zirconium Copper Body + Hardened Steel Inset nozzles for Creality K1, K1 MAX

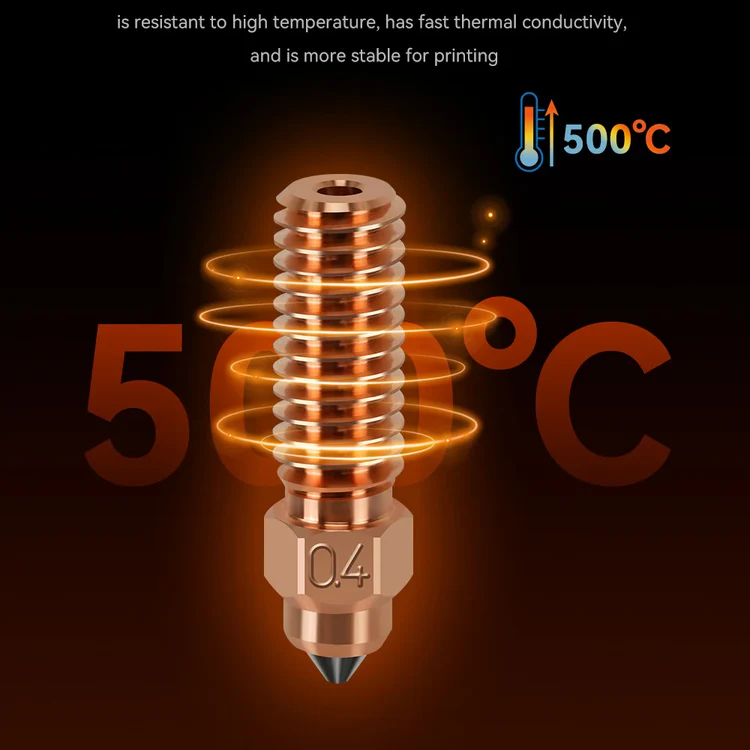

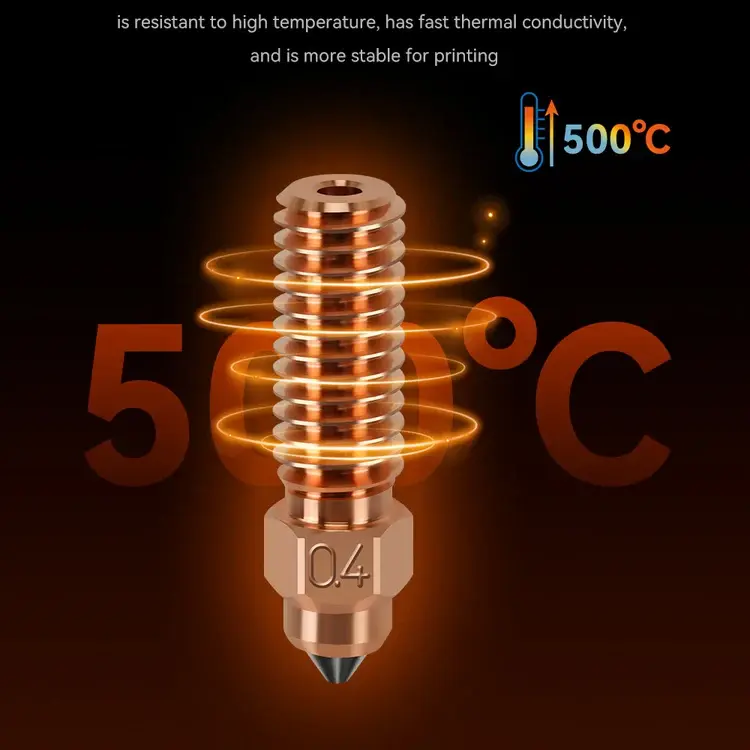

It combines the high thermal conductivity of copper alloys with the wear resistance of hardened steel, allowing you to easily print filaments filled with a variety of abrasive materials such as GF, CF filaments, or luminous while maintaining flowrate and interlayer bond strength and surface quality.

The body of this nozzle has electroless nickel plate finish to prevent oxidation and increase surface hardness.

Compatible:

For Ender 3 V3 KE, Creality K1, Creality K1 Max, CR-M4

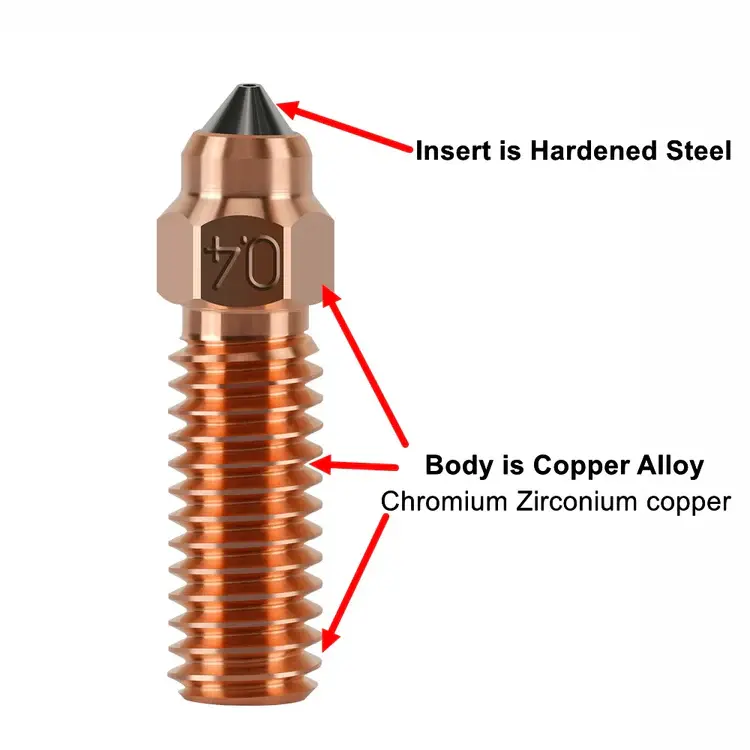

New Bimetal Material Nozzle

Zirconium Copper Body + Hardened Steel inset

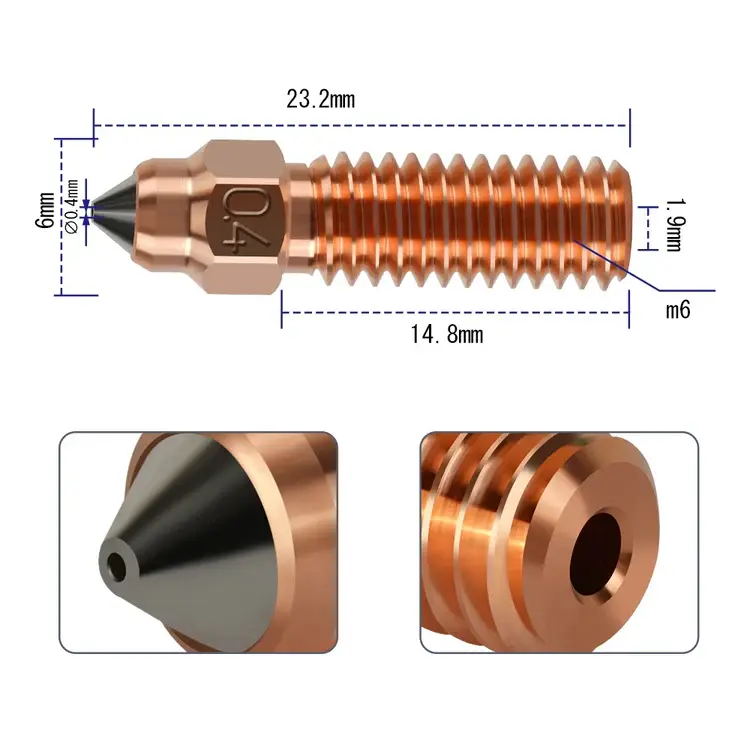

Quick detachable nozzle for easy maintenance

The nozzle has been upgraded to an integrated design, featuring high-quality chrome zirconium copper and hard steel inlay. Quick disassembly and easy replacement.

Suitable for most FDM materials

The outer shell is made of high thermal conductivity chromium zirconium copper material, and the embedded pipeline is made of hardened steel. On the basis of meeting the wear resistance performance, the shortcomings caused by differences in thermal conductivity are solved, and various consumables are supported for printing.

High hardness, Wear resistant and durable

Overall hardening treatment, overall hardness 50 degrees(surface hardness 55-60 degrees.