Bambu Lab A1 3D Printer

Product Features

- Full-auto Calibration

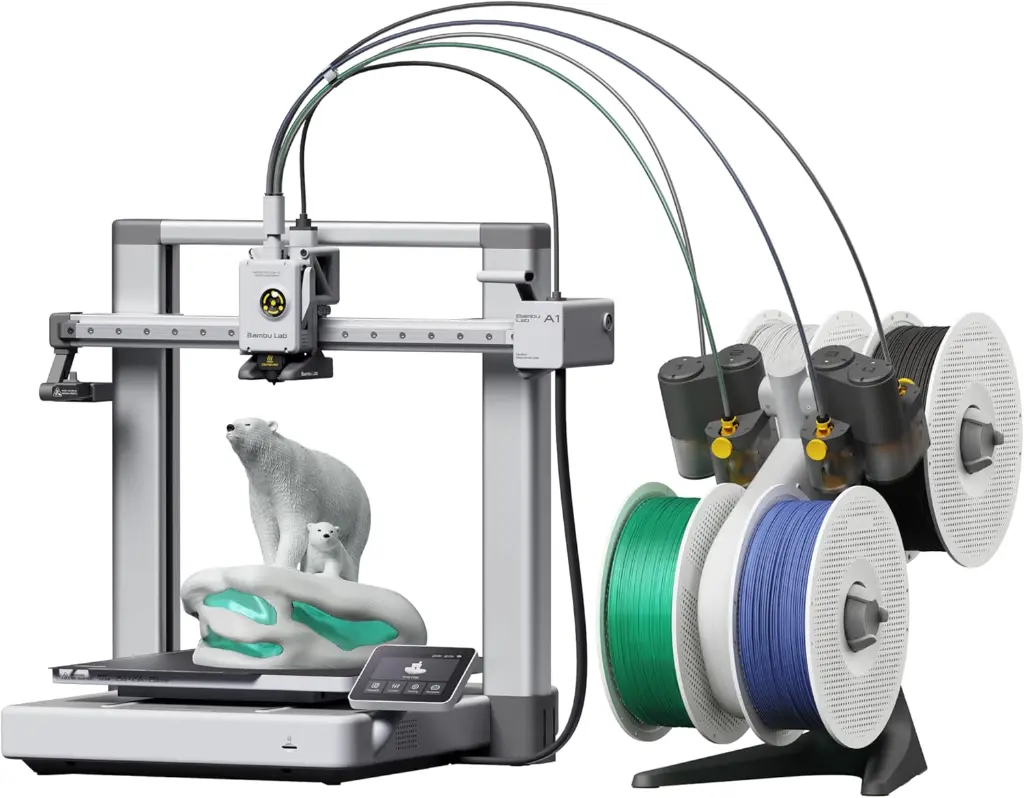

- Multi-Color Printing (Combo Version)

- Active Flow Rate Compensation

- 1-Clip Quick Swap Nozzle

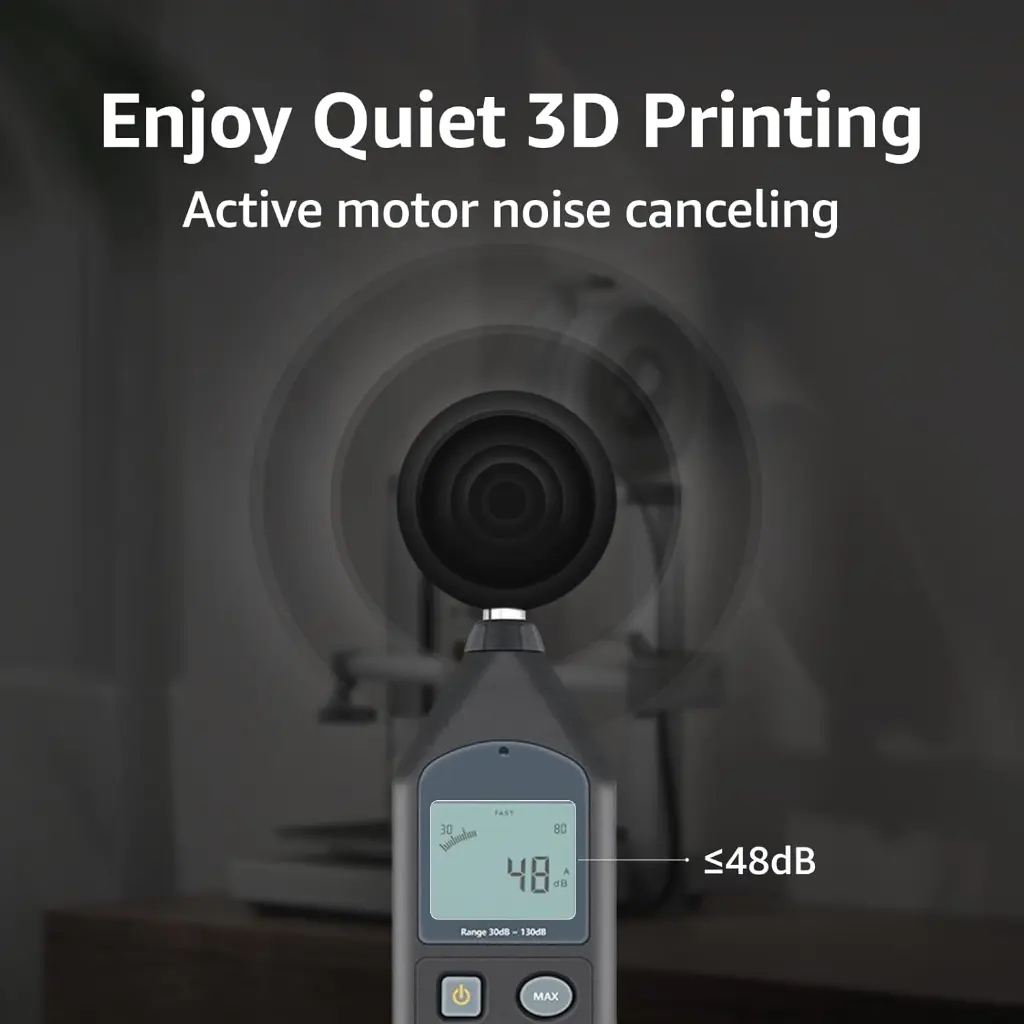

- Active Motor Noise Cancelling

- 256*256*256 mm³ Build Volume

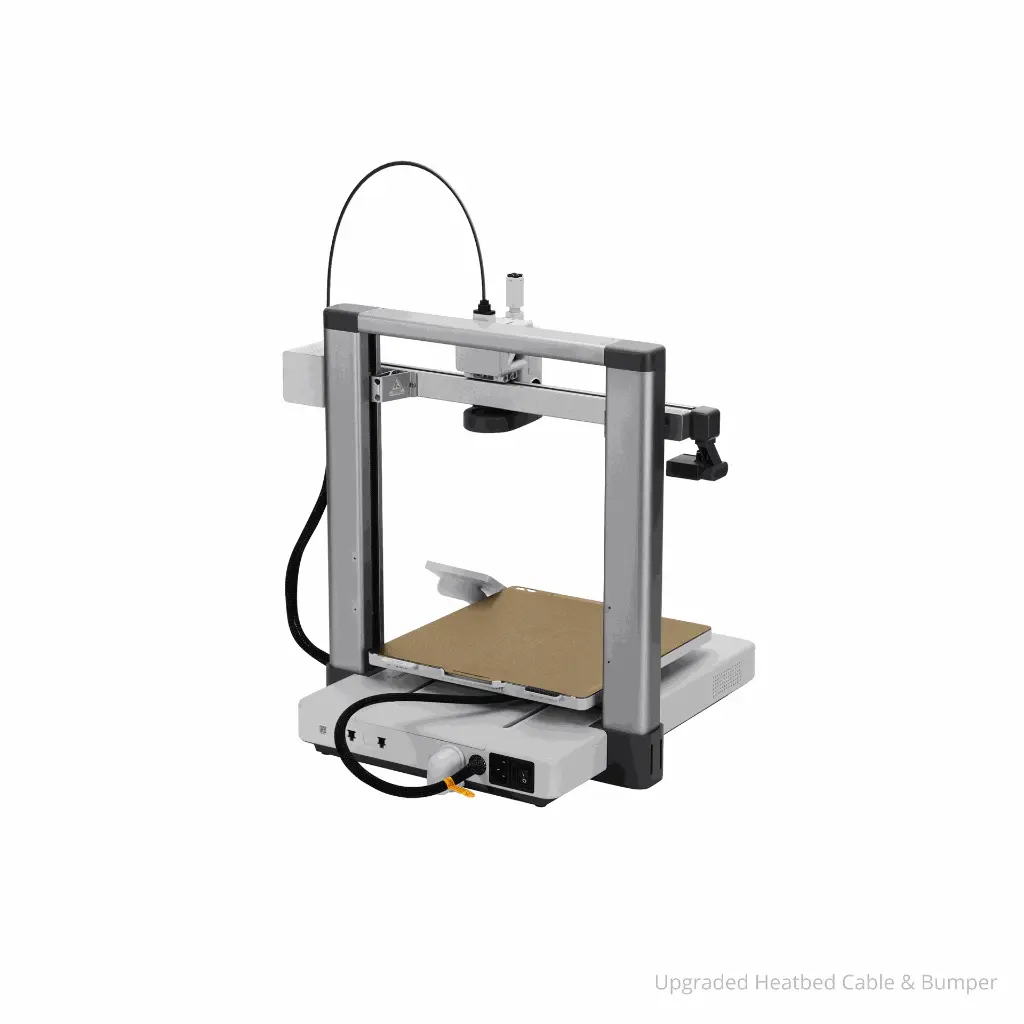

- The upgraded heatbed cable features Kevlar reinforcement, thicker insulation, softer copper, optimized wire winding interval, Nylon sleeving and an extended strain relief.

| Brand: BAMBU LAB |

Why Choose Bambu Lab A1?

Bambu Lab A1 Has

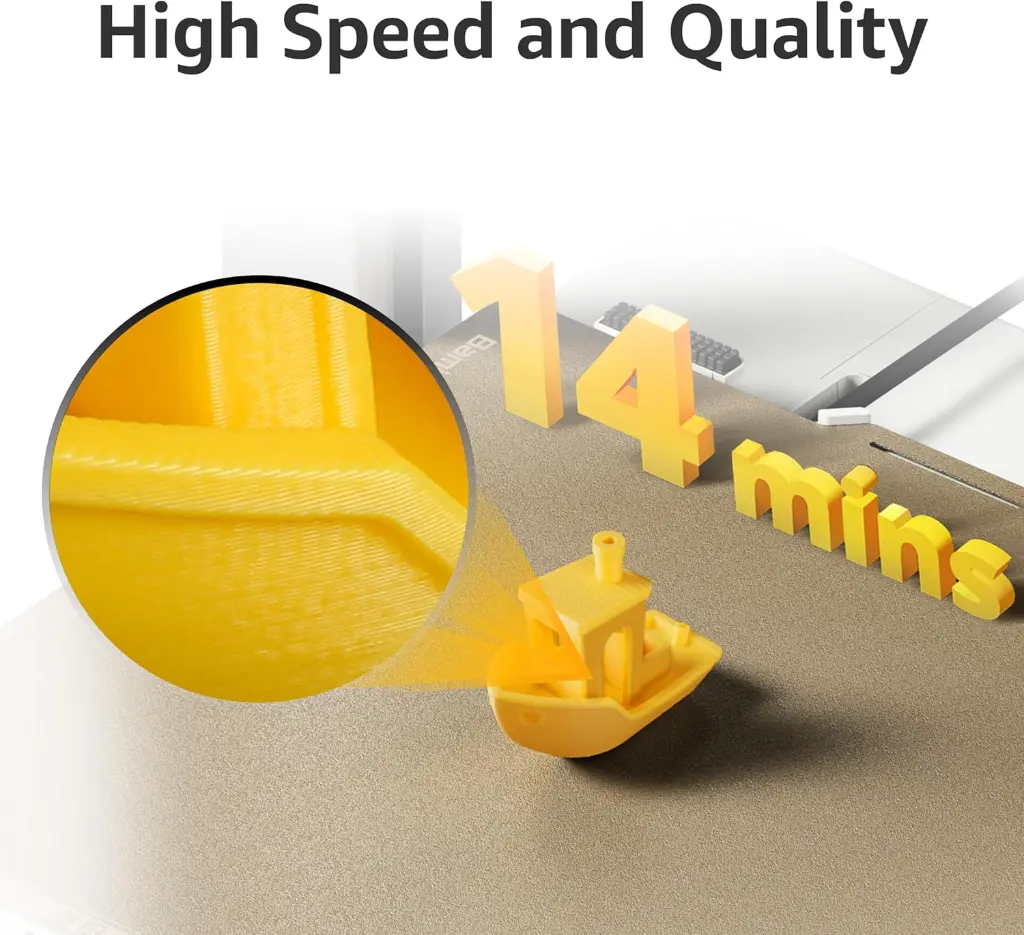

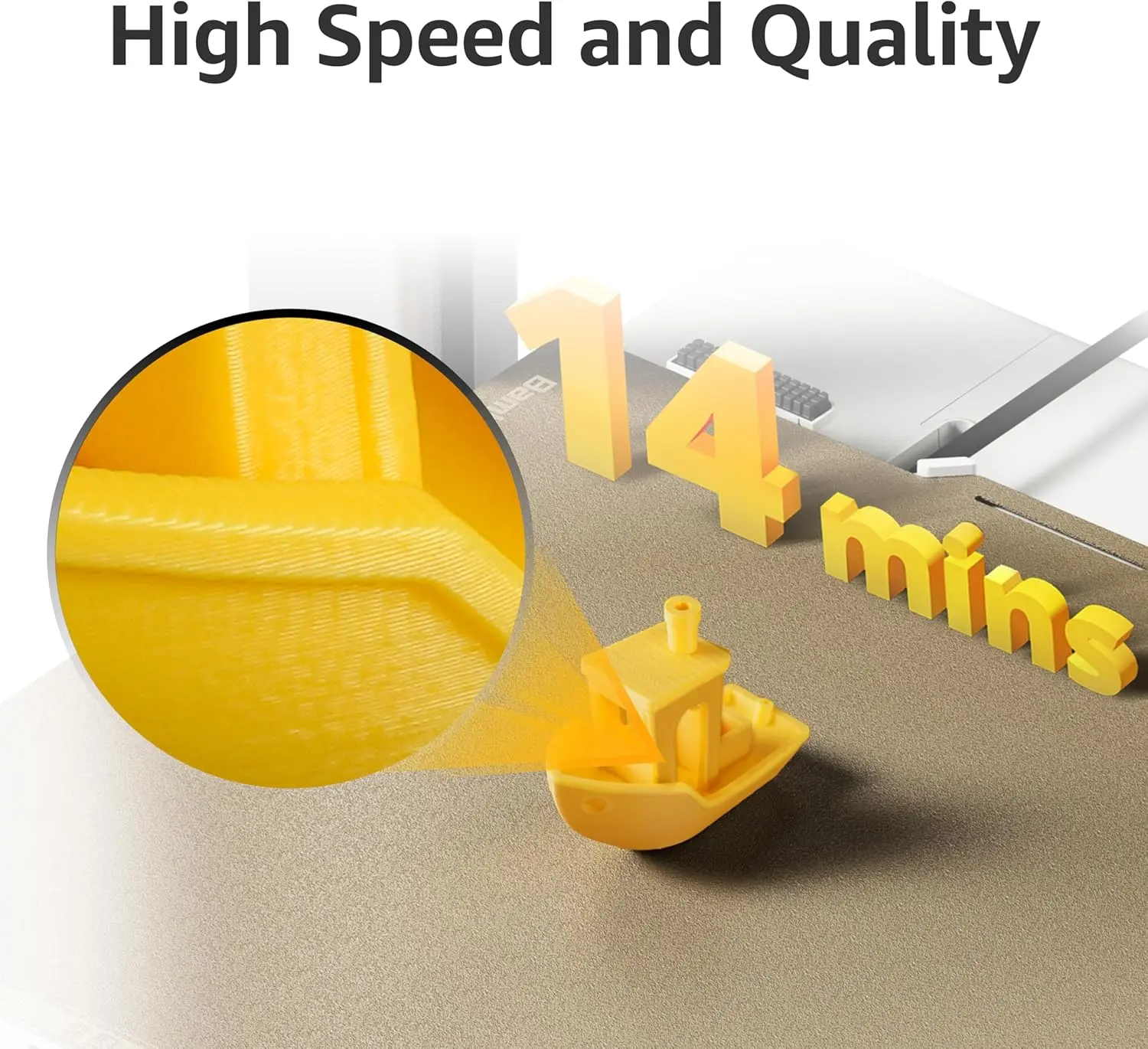

Reliable High Speed - Finish your project on time, everytime

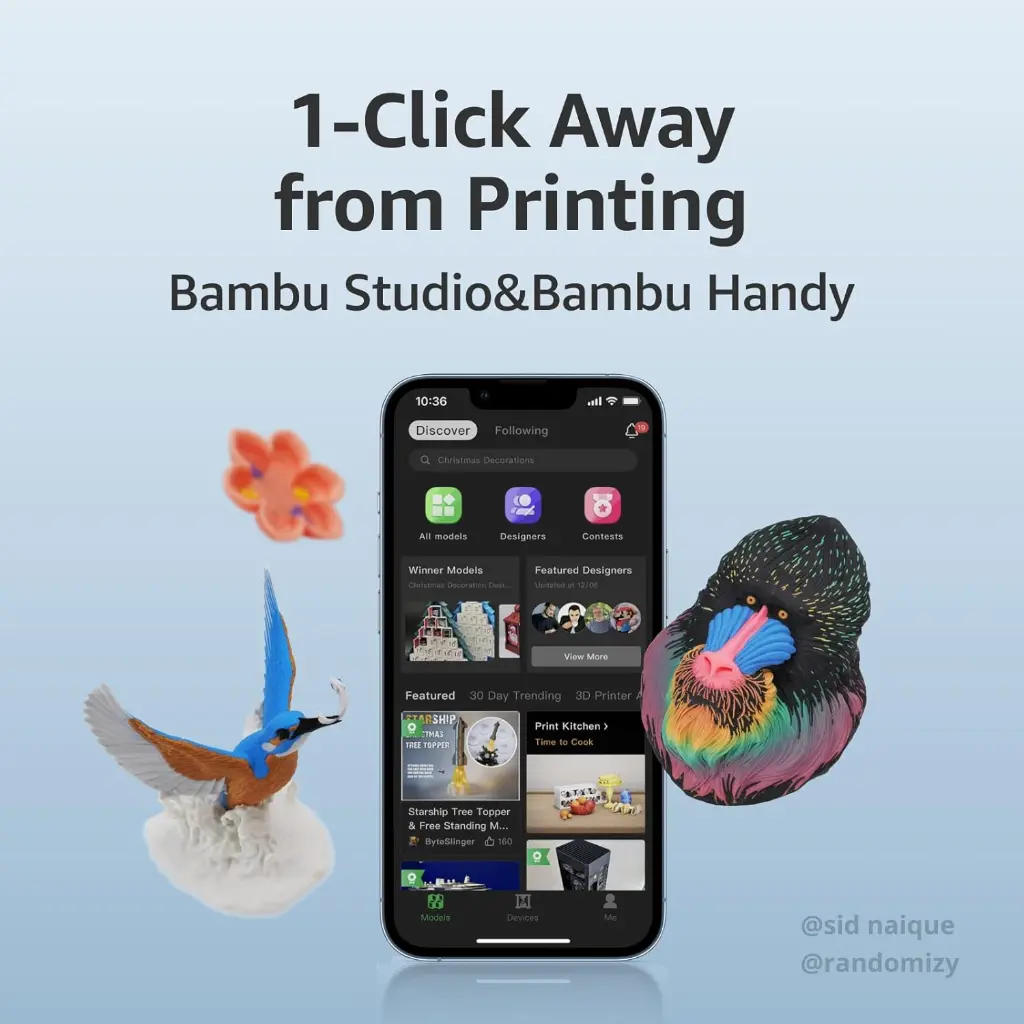

1-click to Print - As easy as your copier

Active Flow Control - Smooth surfaces, sharp edges

Multi-color Printing - The most reliable multi-color system

Multi-color Printing - The most reliable multi-color system

Full-auto Calibration - You don't have to do ANY manual tuning

Active Flow Control - Smooth surfaces, sharp edges

Connected with Privacy in Mind

Start & Control on Whatever Device You Prefer

Not only can you connect your A1 to any device you prefer through Bambu Cloud Service, but you can also do so through LAN-only mode. We offer fully customizable connection options to match your privacy preferences.

Features of Bambu Lab A1 3D Printer

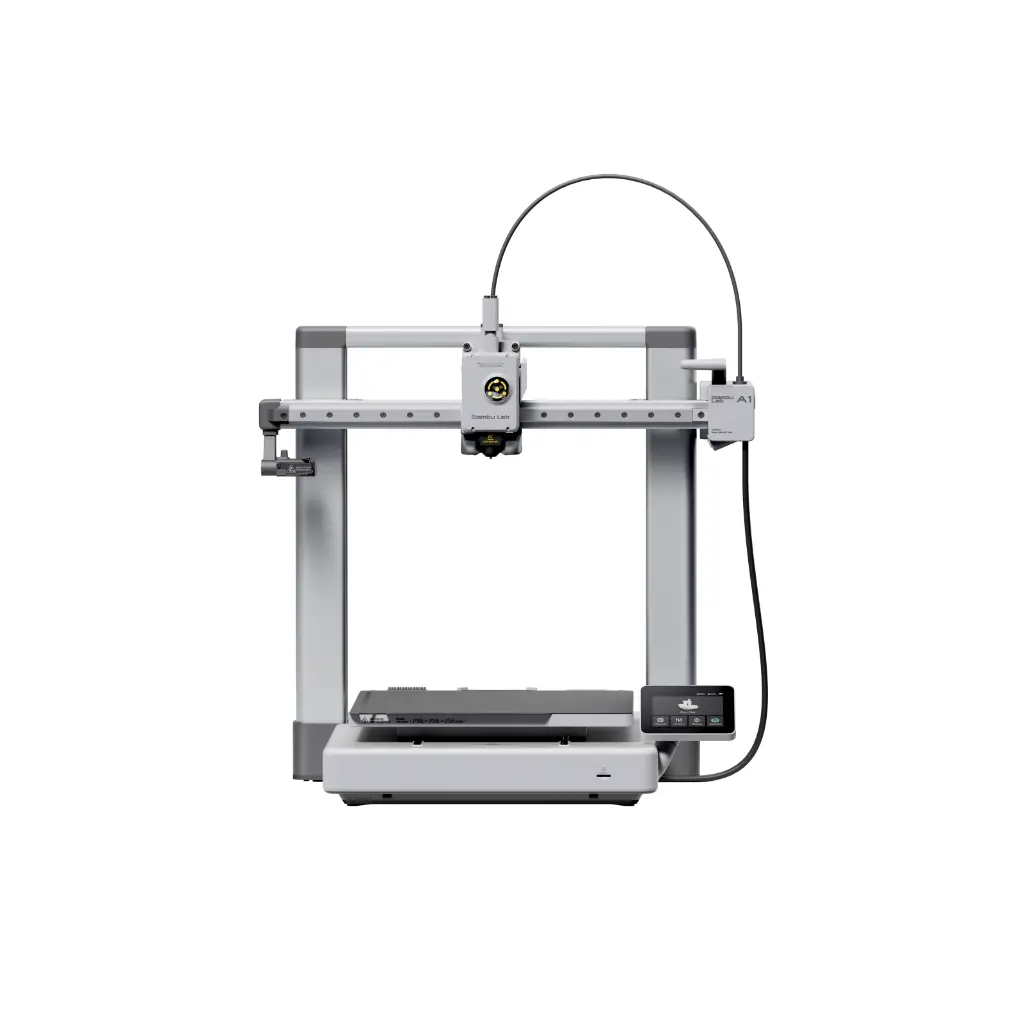

The Bambu Lab A1 is a powerful bed slinger with the speed and quality of a CoreXY 3D printer. The stable frame, robust metal rails and an advanced motion control system take 3D printing to a whole new level with unparalleled precision and impressive quality.

Robust design for more stability

With a robust metal frame made of steel and extruded aluminium, stable bearings and high-quality linear rails, the A1 shows what reliability and durability mean.

The printer uses high-quality linear rails on both the X and Z axes, as well as a metal guide on the Y axis to withstand the wear and tear caused by rapid movements. Regular lubrication can ensure smooth and precise operation.

Quick-swap hotend

The A1 is equipped with a quick-swap all-metal hotend with a 0.4 mm quick-change nozzle made of stainless steel. The hotend is designed for temperatures of up to 300 °C to ensure precise and reliable extrusion.

To enable faster maintenance, the hotend can be replaced with a clip.

Active flow rate compensation

A high-resolution, high-frequency eddy current sensor measures the pressure in the nozzle in real-time. Based on the measured values, the flow rate is actively compensated by a special algorithm or the amount of filament is automatically adjusted in order to always extrude the right amount. This leads to more precise extrusion and improved print quality in many ways.

Fully automatic calibration

► Automatic motor noise suppression: At high speeds, a stepper motor usually produces loud noises. The active motor noise suppression and silent mode, which work with special sensors and algorithms, can reduce the noise level of the A1 to below 48 dB.

► Automatic Z-Offset: Automatically measures how far the nozzle is from the build plate and positions the nozzle to the calculated distance from the build plate.

► Automatic bed leveling : The sophisticated, fully automatic system ensures that the printing surface is always perfectly level without the need for manual work.

► Automatic vibration calibration: Thanks to special sensors on the tool head and the heated bed, a real-time resonance calibration is performed on the X and Y axes before each print.

► Automatic belt tension: Through the so-called vibration frequency calibration, A1 can automatically check the belt tension and trigger an adjustment if necessary.

► Automatic flow dynamics (Pressure Advance): With a special calibration algorithm based on nozzle pressure, no manual adjustments or complex test prints with patterns are required.

Intuitive operation

Thanks to an advanced UI system and an intuitive user interface, operating the 3D printer is easier than ever!

MakerWorld for true artists and explorers

With the MakerWorld platform, Bambu Lab invites the 3D printing community to exchange ideas. The platform combines a variety of functions and offers added value for both beginners and experienced users. Here you can get inspiration, download free (and paid) print models, share your creations with the community, interact with other users and exchange experiences.

Additional features:

- Camera lens cover when deactivating the camera,

- LAN mode for remote control and real-time monitoring,

- Real-time monitoring and control via smartphone app or Bambu Studio,

- The loading and unloading of the filament is done automatically with just the push of a button.

- Improved heating bed cable with Kevlar reinforcement, thicker insulation, softer copper, optimized wire winding, nylon sheathing and extended strain relief.

Technical specifications:

| Device size | 465x410x430mm |

| Net weight | 8.3kg |

| Build volume | 256x256x256mm |

| Housing | Steel, extruded aluminium |

| Hotend | Quick-swap all-metal hotend |

| Nozzle | 0.4mm, stainless steel |

| Max. printing temperature | 300°C |

| Max. heating bed temperature | 100°C |

| Max. print speed | 500mm/s |

| Max. acceleration | 10 000 mm/s² |

| Max. flow rate | 28 mm³/s |

| Supported filaments | PLA, PETG, TPU, PVA |

| Not recommended filaments | ABS, ASA, PC, PA, PET, CF & GF filaments |

| Cooling | Component fan with closed control loop Hotend fan with closed control loop Mainboard fan with closed control loop |

| Sensors | Filament sensor Filament Odometry Recovery from power outage Filament knot sensor |

| Camera | Low rate camera with up to 1080 pixels |

| Device display | 3.5 inch IPS touchscreen |

| Interfaces | WiFi, Bamboo Bus, Micro SD |

| Control | Touchscreen, App, Web |

| Motion control | Dual Core Cortex M4 |

| Supported operating systems | MacOS, Windows |

| Slicers | Bambu Studio and other slicers that can export G-code ( Superslicer, Prusa Slicer, Cura) |

| Voltage | 100-240VAC, 50/60Hz |

| Max. power | 1300W@220V 350W@110V |

Our latest content

Check out what's new in our company !