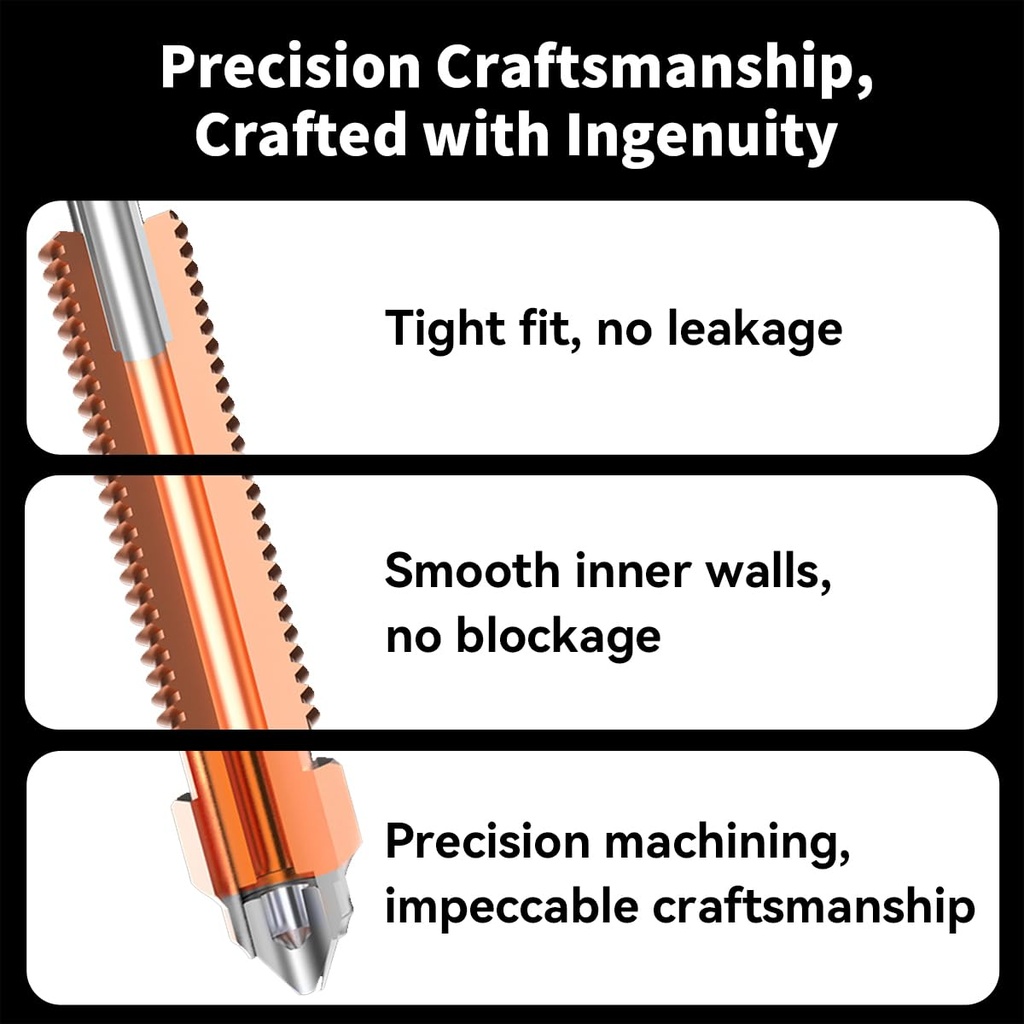

K1 Series Ceramic Heating Block Kit, 3D Printers Hotend with Integrated Quick-Swap Nozzle

| Brand: CREALITY |

- Official Hotend Kit for K1 Series: 100% Creality Official upgrade ceramic heating block kit for K1/K1 Max/K1C 3D printers, our Creality K1 Max upgrades can be used for high speed printing. K1 Max hot end's nozzle clogging depends on the type of filament used and the ambient temperature at the time of printing. K1 series printers are enclosed and may suffer from poor heat dissipation resulting in filament clogging

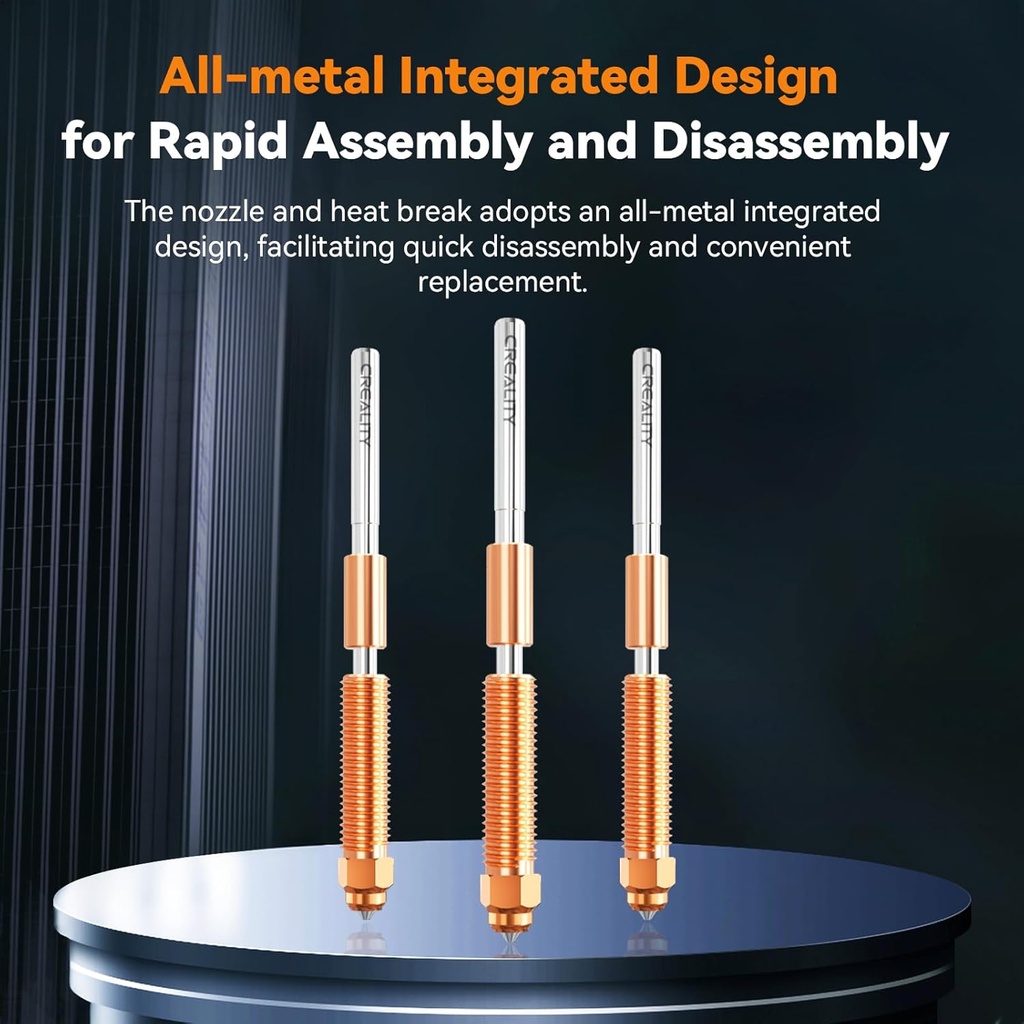

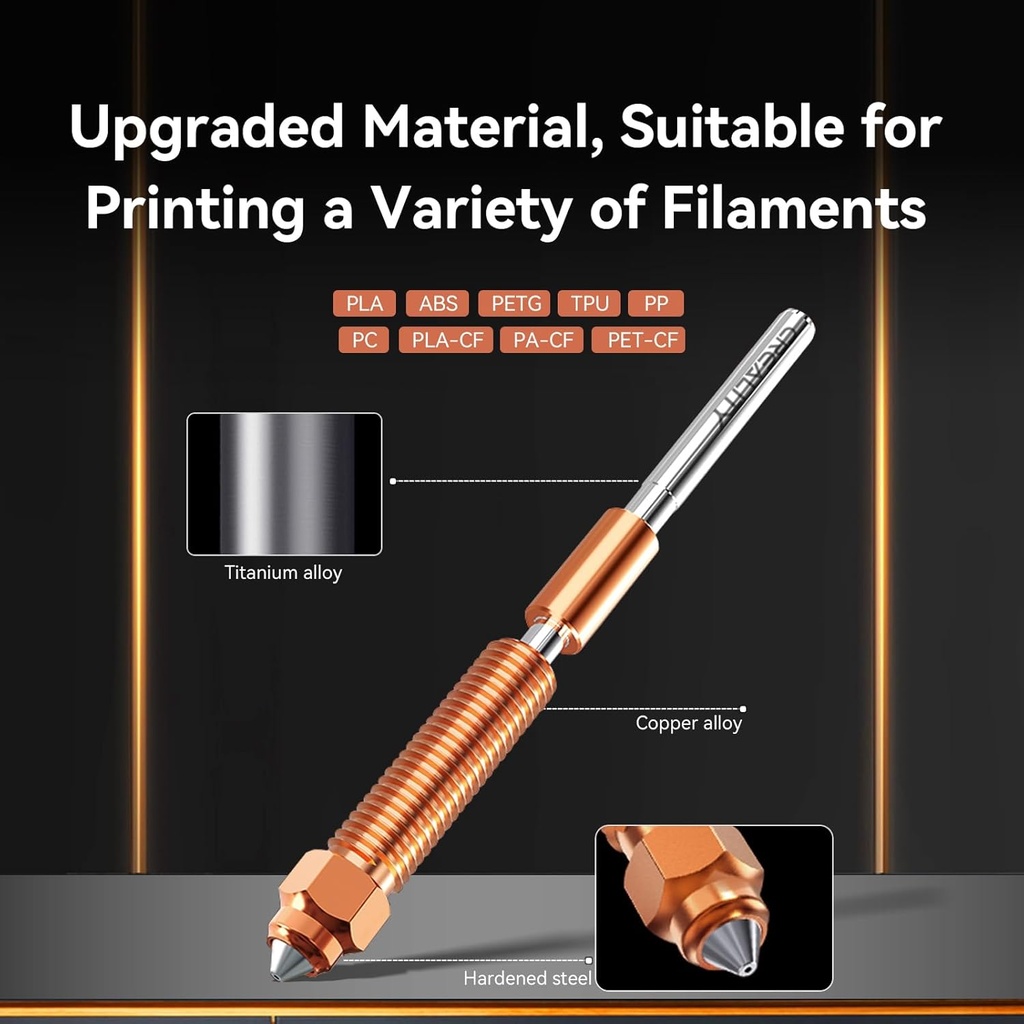

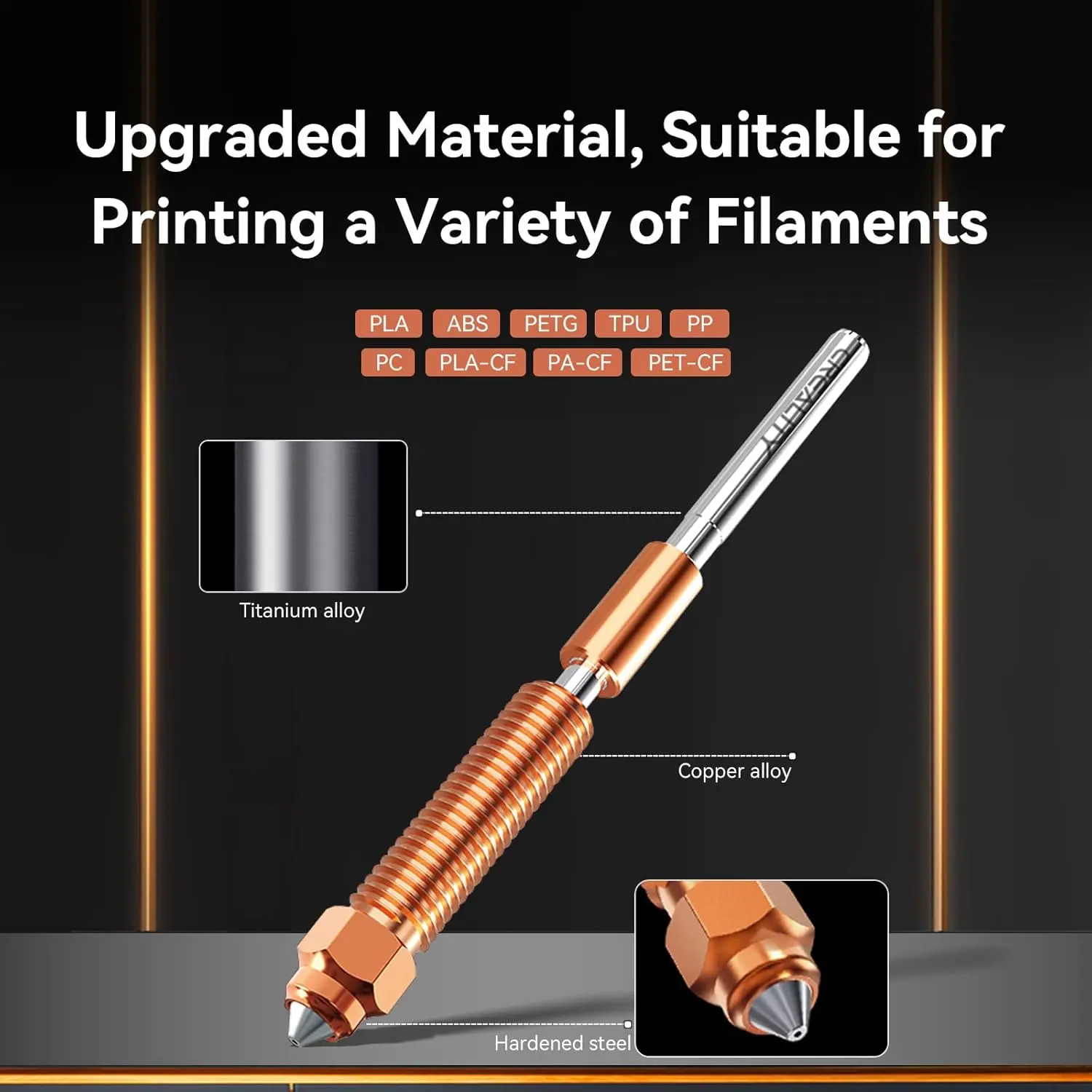

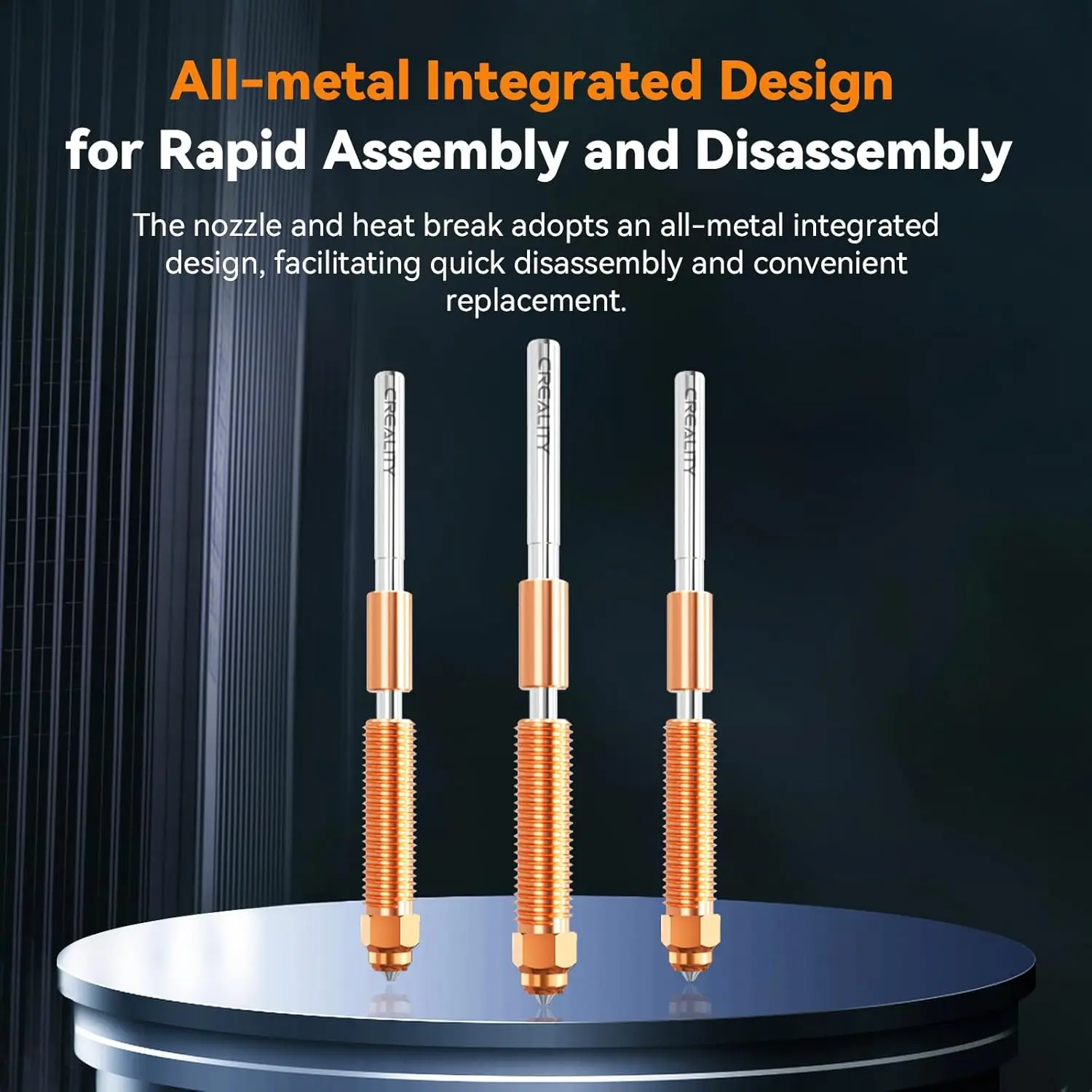

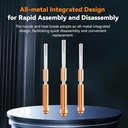

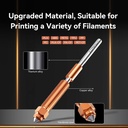

- Upgraded Durable Material&300°C High Temperature Resistance: Creality K1C hotend's throat is made of titanium alloy to minimize heat transfer, our Creality K1 Max nozzle is suitable for printing on a wide range of consumables such as PLA, ABS, PETG, TPU, PP, PC, PLA-CF, PA-CF, PET-CF, and so on. Creality K1 hotend fits for K1/K1 Max/K1C 3d printer, Creality K1C upgrades with integrated quick-swap nozzle has all metal hotend material and heat break for high temperature resistance. Notice: It is recommended that the Creality K1 extruder's printer case be opened during printing to enhance heat dissipation and reduce the risk of clogging

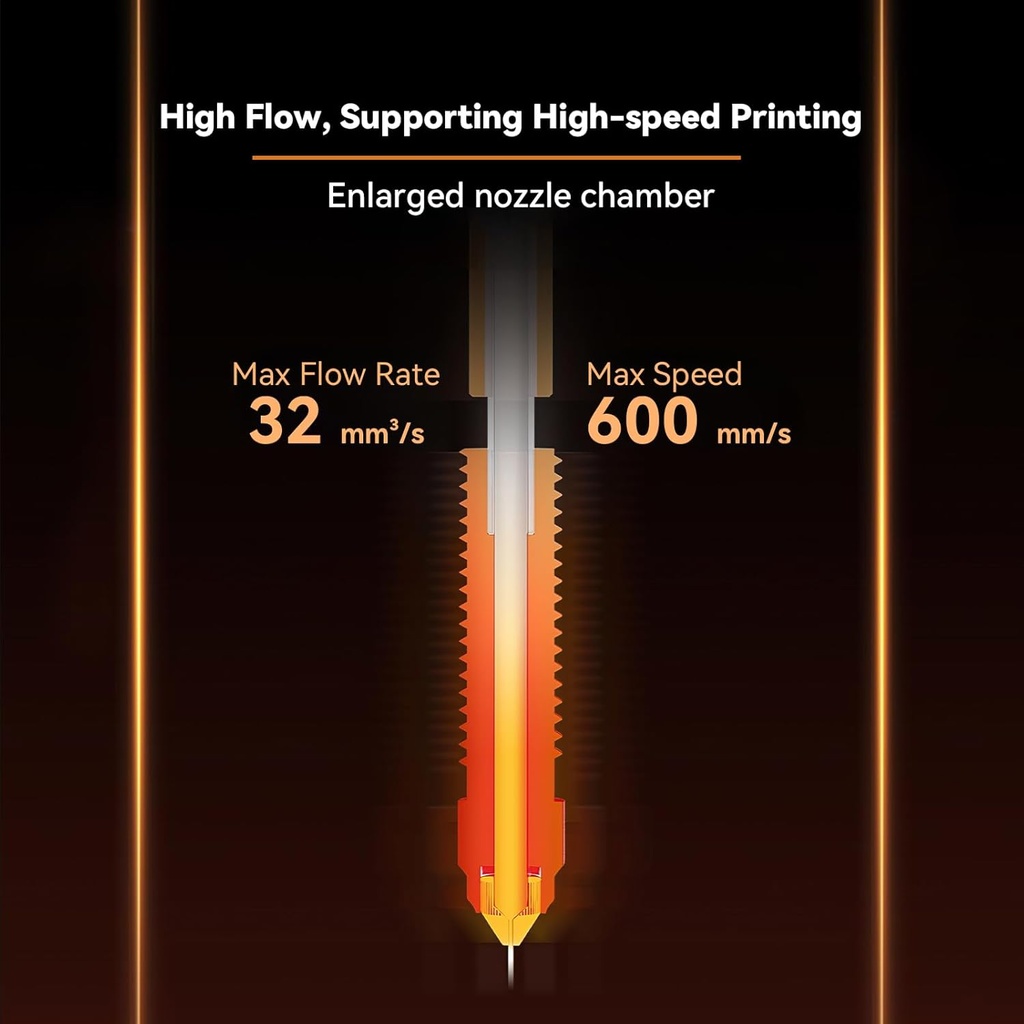

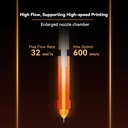

- Up to 600 mm/s High-speed Printing: Creality K1C hotend with a 30% increase in the entire hotmelt section, achieving a maximum flow rate of up to 32 mm³/s. Creality k1 parts allows for printing speeds up to 600 mm/s. K1 Max hotend's burr-free orifice is less likely to clog the material and provides stable printing

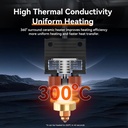

- High Flow Rate: The Creality K1 hotend upgrades is equipped with a rugged and powerful 60W 360° encircling ceramic heating ring. Creality K1 hotend's 360° surrounding ceramic heater improves the heating efficiency and heats up to 200°C in less than 40 seconds

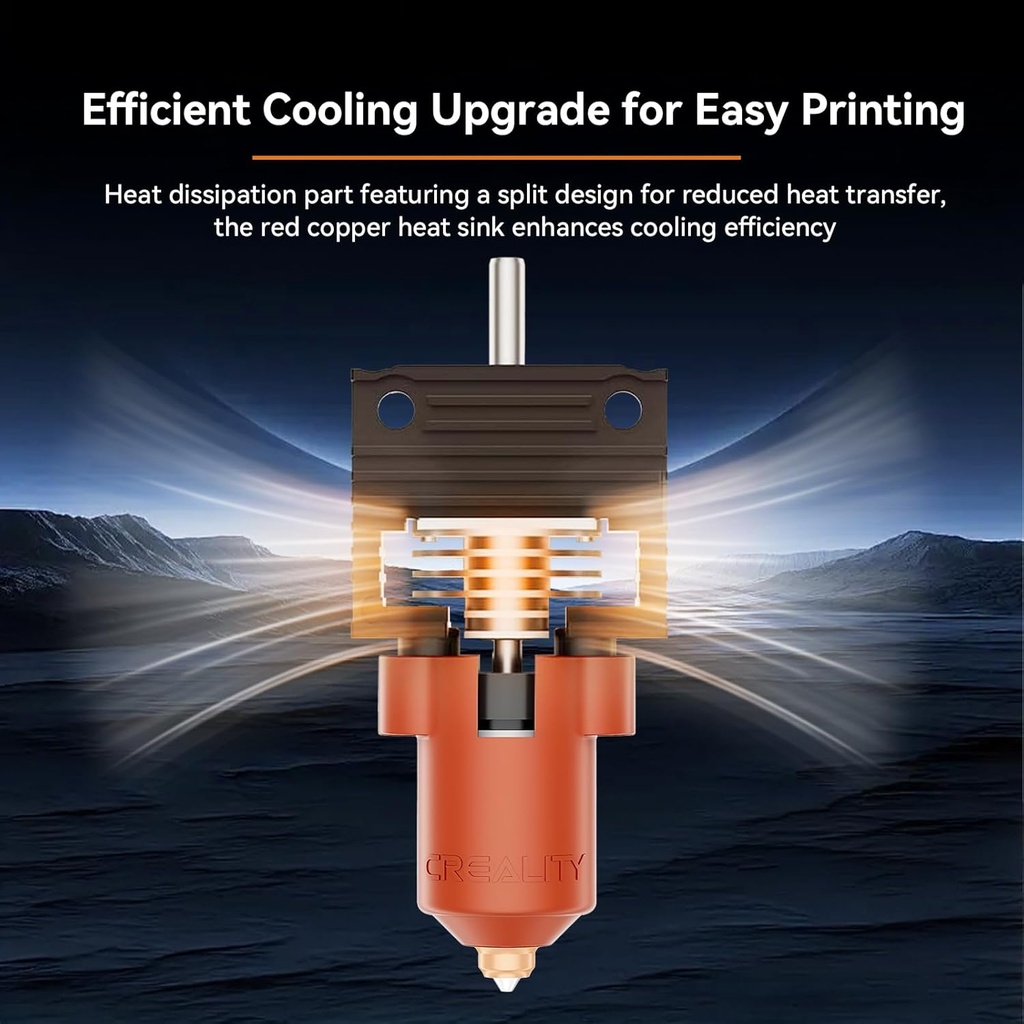

- Efficient Cooling Upgrade for Easy Printing: 3D printers' K1 Max hotend's heat dissipation part adopts split design to reduce heat transmission; the ceramic heating block's surface is nickel-plated to improve abrasion resistance and increase luster. Notice: Please ensure good adhesion on the first printing layer; if necessary, re-adjust the level and apply adhesive to improve adhesion. Nozzle clogging can occur with improper adhesion of the first layer, causing the nozzle to pick up loose print material and deposit it outside as it moves

?unique=2eb30df)

?unique=2eb30df)