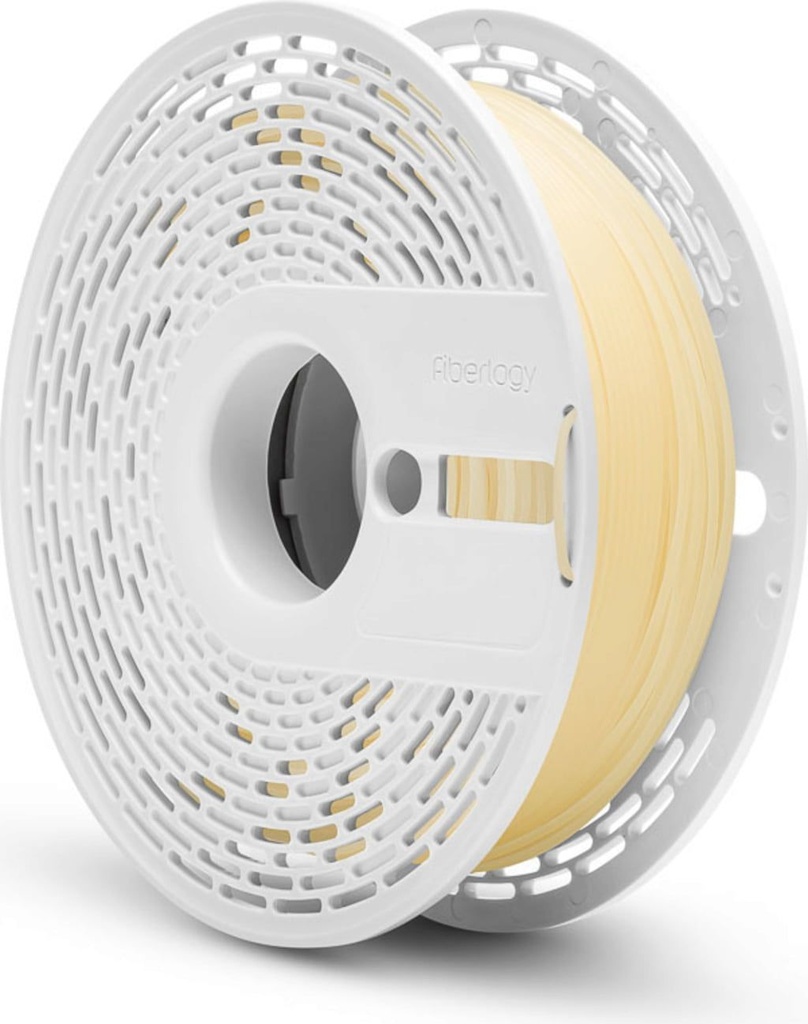

Eryone PVA Filament 1.75mm, 0.5kg/roll in Pakistan

| Brand: ERYONE |

PVA & Support Material - Soluble filaments for support structures

PVA filaments are water-soluble 3D printing materials that serve as support when printing objects. They are used to support overhanging parts or complex structures in 3D printing that would be difficult or impossible to produce without PVA. After the print object is fully printed, the PVA supports simply dissolve in water.

Breakaway support filaments are a sub-category of support filaments specifically designed to be easily removed from the printed object. They are used to support overhanging parts or complex structures in 3D printing that would be difficult or impossible to produce without support filament. After the print object is fully printed, the Breakaway Support filaments can be easily removed by hand.

In the 3D print sector, PVA 3D filament (polyvinyl alcohol) is a critically important family of materials. Its water solubility is very valuable because it allows support scaffolds to be printed on dual/multi extruder machines and later removed with ease. PVA offers several useful characteristics that make it almost perfect as a support material. These include: high water solubility, high stickiness in the melted state, and a print temperature range of 180-210°C.

PVA was first produced by Fritz Klatte and patented in Germany in 1912. Initial commercialization occurred in Japan in the late 1930s, with the Kuraray company producing low-cost Vinylon and Kuralon fibers. These came in various levels of insolubility and each fit a different application. Some of the PVA fibers were made to: modify concrete, reinforce rubber, or enable fiberglass to better resist shock and shrinkage.

PVA’s basic form is powder. The 3D print filament is formed by melting and extruding that basic material. This filament is very uniform in its properties and is sold in packaging that prevents exposure to atmospheric moisture. Such exposure would degrade the material and make the filament rolls congeal into a softened mass. This article will further discuss PVA 3D printing filament and examine its composition, properties, and recommended 3D printer settings.

What is PVA 3D Printing?

Within the realm of 3D printing, PVA is solely used to construct support scaffolds. It serves to support structures that would otherwise be impossible or ungainly to print. Once the printing is finished, the supports can be washed away. PVA supports are extruded by a second extruder but are otherwise built up in exactly the same way as the part’s primary material. For more information, see our guide on everything you need to know about 3D printing.

What is the Composition of PVA Filament?

The typical PVA 3D printing filament available on Amazon is either pure PVA (polyvinyl alcohol) from a single source or a blend of several PVA materials. These PVA materials are meant to achieve the right balance of adhesion, strength, water solubility, and melt-flow characteristics. PVA is a synthetic polymer derived from the hydrolysis of polyvinyl acetate with the nominal formula [CH2CH(OH)]n.

Filament for 3D printing is supplied in various diameters, but it is chemically pure PVA without any additives and co-polymers other than coloring agents. Some variation in molecular weight is normal between manufacturers – it varies based on the n value in the chemical formula. This variation in molecular weight affects melt temperature and density, so Esun PVA filament may not have exactly the same characteristics as Flashforge PVA filament, for example.

What Are the Properties of PVA Filament?

Some of the desirable properties of PVA filament are:

- White in appearance (unless colored by addition).

- Translucent.

- Resistant to organic solvents and oils.

- Highly water-soluble, depending on the degree of hydrolysis in its manufacture and its molecular weight.

- Highly rated for tensile strength, compared with many polymers used in 3D printing.

- More flexible and wear-resistant than many other polymers.

Comparison of PVA Filament Properties

A comparison of the PVA filament properties to HIPS (high impact polystyrene) and ABS (acrylonitrile butadiene styrene) is shown in Table 1 below:

Table 1: Comparison of PVA vs HIPS vs ABS

| Property | PVA | HIPS | ABS |

|---|---|---|---|

Ultimate Strength | 78MPa | 32MPa | 40MPa |

Stiffness | Low | High | Moderate |

Durability | Quite high | High | Quite high |

Maximum Service Temperature | 75°C | 100°C | 98°C |

Thermal Expansion | Quite high | Quite high | High |

Density | 1.23g/cm3 | 1.03 - 1.04g/cm3 | 1.04g/cm3 |

Relative Price (this group) | High | Moderate | Low |

Relative Printability | Quite poor | Moderate | Quite good |

Extruder Temperature | 185 - 200°C | 230 - 245°C | 220 - 250°C |

Hygroscopic | Very high | Very low | Very low |

Solubility | Highly soluble in warm water | Highly soluble in D-Limonene | No relevant solubility |

What Are the Limitations of 3D Printing with PVA?

PVA is a moderately good print material during the actual printing process. It is more durable, stronger, and more temperature resistant than PLA (Polylactic Acid). However, models made of PVA have a short usable life. Under normal conditions, they will absorb moisture, swell, and soften much sooner and to a greater degree than PLA prints. But under dry conditions, PVA can be a useful build material. For a support material, PVA is unfortunately quite expensive. It is also compatible only with certain model materials that have similar melting temperatures.

Why is PVA Used in 3D Printing?

The soluble nature of PVA makes it an ideal choice for the scaffolding that supports overhanging features. An additional benefit is that PVA adheres very well to build materials, allowing precise and slump-free printing.

How to Use PVA in 3D Printing

To get good results in prints using PVA filament, here are useful things to remember:

- Store the PVA in dry conditions. If it has absorbed moisture, heat it between 45-55 °C and keep it at that temperature for at least an hour before printing.

- Use an ooze shield or wipe wall during printing. The use of an ooze shield ensures good extruder priming and prevents runs and threads from adhering to the build and potentially interfering with the subsequent layers.

- Use 30% density in the support features and 70-100% density at the model interface layers as starting values.

- Setting the upper separation distance to zero layers makes for more accurate prints and better surface quality.

- To dissolve PVA filament, immerse the whole part in warm water and wash remnants away once fully softened.

What Are the Best Configuration Settings for PVA 3D Printing?

Listed in Table 2 below, are the recommended configuration settings for PVA:

Table 2. PVA 3D Printer Settings

| Printer Settings | Value |

|---|---|

Nozzle temperature | 215–225 ˚C - varies with manufacturer |

Bed temperature | 45-60 ˚C, validate and adjust in your printer |

Print speed | 30 mm/s |

Extruder fan speed | 50%, assess your own print and adjust |

Retraction speed | 40 mm/s |

Retraction distance | 5 mm |

Flow of filament | 25-30 mm/s for a 0.4 mm nozzle |

Layer height | 50% of nozzle diameter, adjust as required |

Print bed | Glass, with a layer of glue stick (Magigoo) |

Heated chamber | Off unless required for build material |