Bambu Lab PLA-CF in Pakistan

- Carbon Fiber Texture & Minimized Layer Lines

- Improved Mechanical Properties

- Stablized Printing Dimension

- Comes with Basic Reusable Spool

- Diameter: 1.75mm +/- 0.03mm

Cautions for Use

- 0.2 mm Nozzle Not Compatible

- Stainless Steel Nozzle Not Recommended

- Dry before Use for the Highest Print Quality

- AMS Compatible

| Brand: BAMBU LAB |

| Weight: 1Kg |

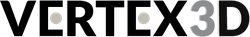

Bambu PLA-CF is carbon fiber reinforced PLA with improved stiffness and strength. PLA-CF is easy to print and beginner-friendly like regular PLA. It is AMS compatible with low clogging risk at high-speed printing. The prints are in matte finish with almost invisible layer lines, which make it suitable for printing general engineering parts or models requiring a better appearance, like bike frames, brackets and toys.

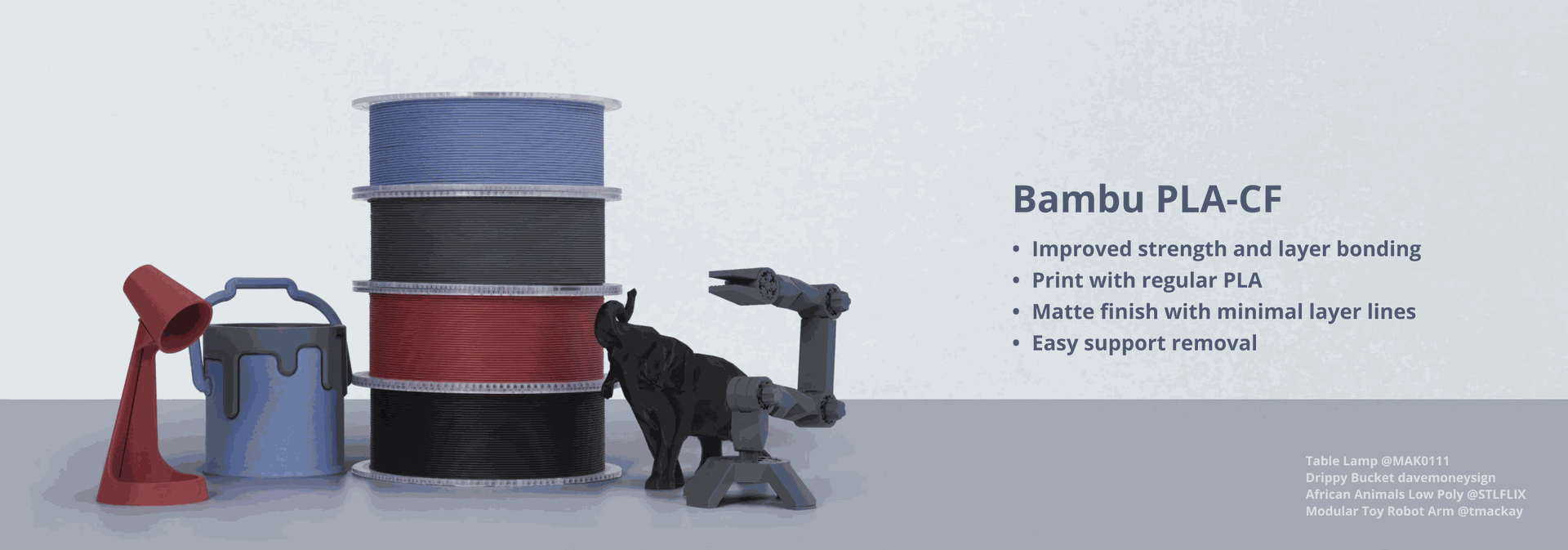

Carbon fiber texture & Minimized layer lines

The addition of carbon fiber gives prints a unique matte finish and effectively hides layer lines, providing a smooth, premium look.

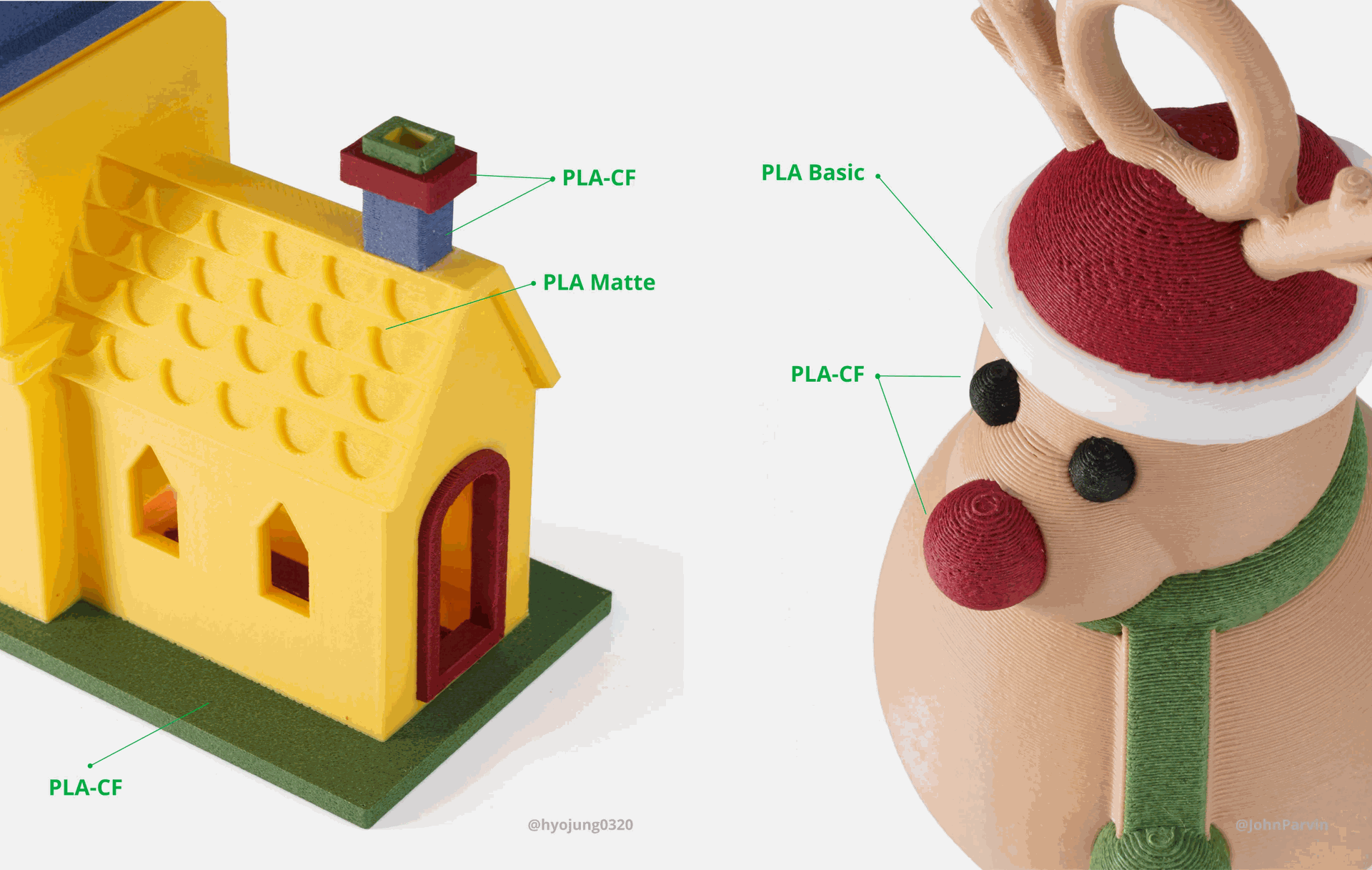

Display of Prints

Bambu PLA-CF could be paired with any PLA series filament to make your prints more colorful and achieve various texture requirements.

Mechanical Properties Comparison

| PLA Matte | PLA-CF | Improved % | |

| Tensile Strength - XY/MPa | 32 | 38 | 19% |

| Tensile Strength - Z/MPa | 25 | 26 | 4% |

| Bending Strength - XY/MPa | 53 | 89 | 68% |

| Bending Strength - Z/MPa | 32 | 49 | 53% |

| Bending Modulus - XY/MPa | 2360 | 3950 | 67% |

| Bending Modulus - Z/MPa | 2040 | 2260 | 10% |

| Impact Strength - XY/(kJ/m²) | 19.2 | 23.2 | 20% |

| Impact Strength - Z/(kJ/m²) | 6.6 | 7.8 | 18% |

*Drying PLA is recommended for humid environments at 55 °C for 8 hours before printing.

Accessory Compatibility

| Recommended | Not Recommended | |

| Build Plate | Cool Plate, High Temperature Plate or Textured PEI Plate | Engineering Plate |

| Hotend | Hardened Steel Nozzle (0.4 / 0.6 / 0.8 mm) | Stainless Steel Nozzle (0.2 / 0.4 mm) |

| Glue | Bambu Liquid Glue Glue Stick |

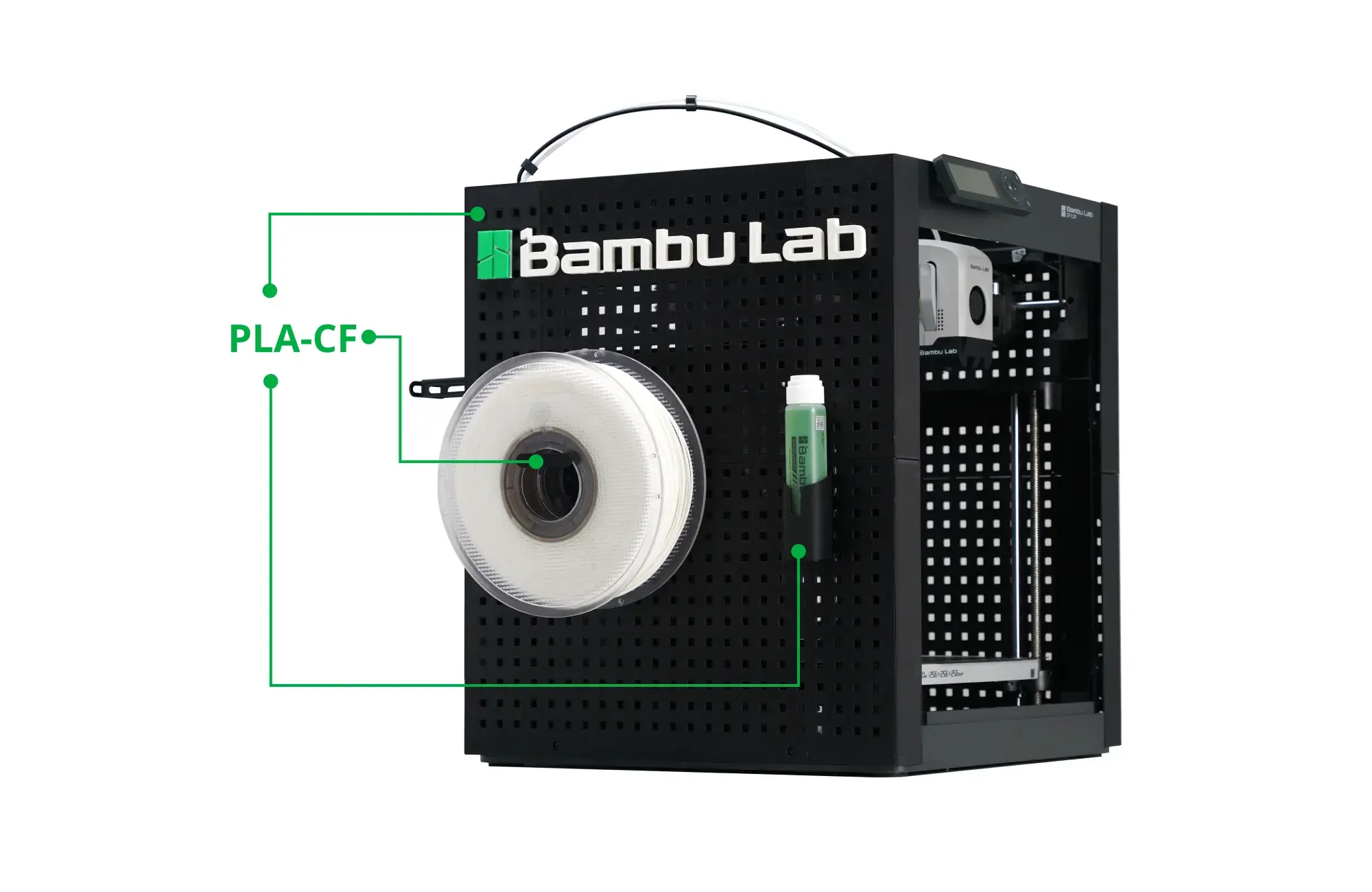

RFID for Intelligent Printing

All printing parameters are embedded in RFID, which can be read through our AMS (Automatic Material System).

Load and print! No more tedious setting steps.

| Recommended Printing Settings | |

| Drying Settings (Blast Drying Oven) | 55 °C, 8 h |

| Printing and Keeping Container's Humidity | < 20% RH (Sealed, with Desiccant) |

| Nozzle Temperature | 210 - 240 °C |

| Bed Temperature (with Glue) | 35 - 45 °C |

| Printing Speed | < 200 mm/s |

| Physical Properties | |

| Density | 1.22 g/cm³ |

| Vicat Softening Temperature | 69 °C |

| Heat Deflection Temperature | 55 °C |

| Melting Temperature | 165 °C |

| Melt Index | 3.7 ± 0.6 g/10 min |

| Mechanical Properties | |

| Tensile Strength | 38 ± 4 MPa |

| Breaking Elongation Rate | 8.4 ± 3.2 % |

| Bending Modulus | 3950 ± 190 MPa |

| Bending Strength | 89 ± 4 MPa |

| Impact Strength | 23.2 ± 3.7 kJ/m² |

?unique=1b25b45)